Environmental Engineering Reference

In-Depth Information

Wood industrial residues are used as raw materials and are delivered to the plant in the

form of pellets (chemical and elemental composition in Table 1). The results of the

biorefinery systems are shown in comparison with a fossil reference system providing the

same amount of energy and chemical products from fossil sources. The software tool Gemis

is used to model LCA calculations and as database source (Gemis, 2008).

Environmental concerns are focused on energy and greenhouse gas (GHG) balances of

biorefinery and fossil reference systems, because reduction of GHG emissions and decrease

of fossil fuel consumption are two driving forces of biomass utilization strategies. As a direct

consequence of the definition, a biorefinery is characterized by multiple useful outputs (both

energy and material products). This fact gives rise to an allocation issue, which was addressed

using different allocation methods.

Finally, biorefinery system performances are investigated by means of several indices

and indicators such as conversion yields and mass, energy, exergy and C efficiencies.

4.2.1. Biorefinery: scope and system boundaries

Wood industrial residues are the raw materials for this biorefinery system. The feedstock

is assumed to be collected from industries, transported to a pellet facility (20 km), where it is

dried and pelletized, and transported to the biorefinery plant (100 km). The GHG emissions

estimated for collecting, processing and delivery of raw materials to biorefinery gates are

equal to 1.94 g CO

2

-eq./MJ

pellets

, while the primary fossil energy consumption is 8.47

kJ/MJ

pellets

(Gemis, 2008).

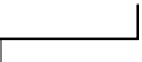

MTHF

H

2

Acid

treatment

Chemical

reactions

Furfural

Furan resins

C5

sugars

O

2

FUMA

CO

2

Pre-

treatment

Feedstock

Hydrolysis

Fermentation

Distillation

C6

sugars

Bioethanol

Fertilizer

Legend

Waste-

water

Anaerobic

digestion

Biogas

Upgrading

Biomethane

Feedstock

Process

Lignin &

residues

Alkaline water

electrolysis

Combustion

Electricity

Hydrogen

Output not

exploited

Intermediate

Heat

Energy

Product

Material

Product

Oxygen

Figure 11. Process scheme of the investigated biorefinery.

This biorefinery produces bioethanol from fermentation of C6 sugars, furfural from

hydrolysis of C5 sugars (which is then chemically converted to fuel additive and other

chemicals), electricity and heat from combustion of lignin and residues, hydrogen and oxygen

through alkaline water electrolysis and biomethane and fertilizer via anaerobic digestion of

wastewaters (Figure 11).