Travel Reference

In-Depth Information

The first step in laying track is to carve the path (it's called the

subgrade

) out of the terrain and, as much as possible, level it off.

This is done by removing earth from the high spots and using it

to fill in the low areas. Look for this as you travel. You'll imme-

diately be aware of the terrain rising and falling as it passes your

window while the actual roadbed remains more or less level.

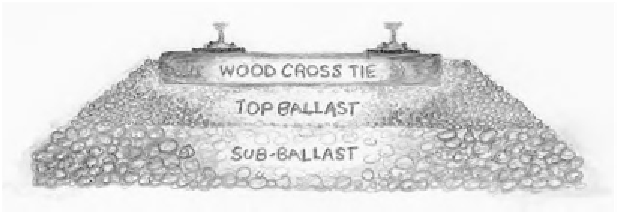

Once this subgrade has been prepared, two layers of ballast

are added. The first is coarse gravel; the second is crushed rock

or crushed slag. These two layers of ballast can be as much as 2.5

feet deep, depending on the condition of the subgrade.

Next come the cross ties—traditionally wood, but more and

more made from concrete—which are embedded in the top bal-

last. Wooden ties are placed a foot apart (3,000 for every mile

of track); concrete ties are larger and heavier and are placed two

feet apart. Concrete ties are used more in areas where there is

heavy or high-speed train traffic. They also should last up to 25

years before needing to be replaced. Under the same conditions,

a wooden tie, even when it has been chemically treated to resist

rotting, will only last for about seven years.

Railroad track is laid by fastening rails to wood or concrete cross ties on top of two

layers of gravel or crushed rock.

When wooden ties are used, heavy metal plates, called

tie

plates

, are placed on the ties. The rails are laid over the tie plates,

Search WWH ::

Custom Search