Biomedical Engineering Reference

In-Depth Information

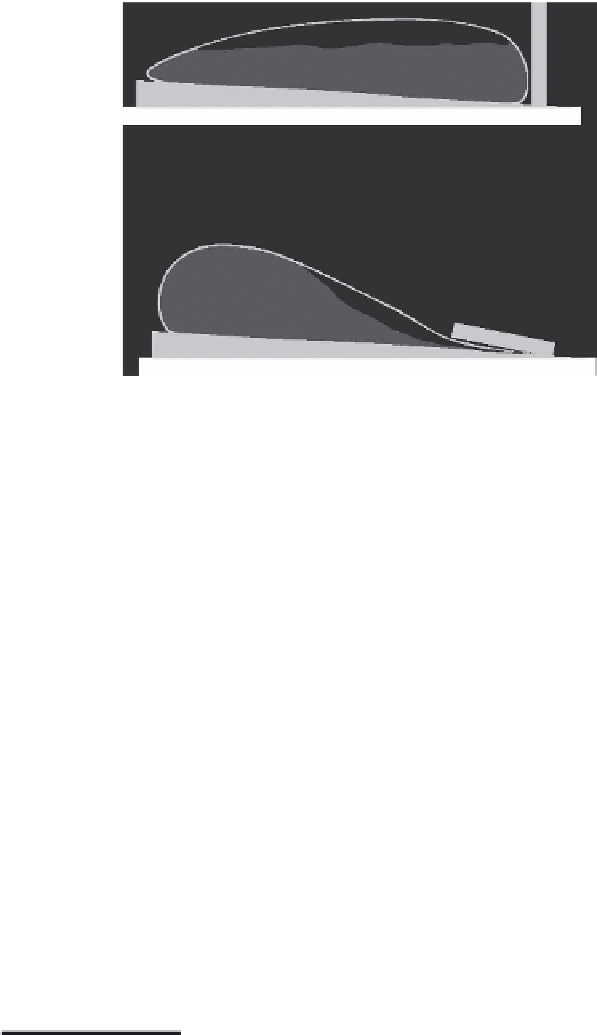

FIGURE 5.4

New concept of mixing in MayaBioReaxtors by pushing the liquid against an incline.

AppliFlex, the BIOSTAT CultiBag Rocking Motion, the BioWave, the CELL-

tainer, the Wave Bioreactor, the Wave and Undertow Bioreactor (WUB), and

the most recently introduced MayaBioReactors, which have a stationary sur-

face and require the least amount of energy input (Figure 5.4).

Perhaps the equipment suppliers' profit margins were not large enough

or perhaps they understood the psychology of the industry well enough to

know that it would not be easy for Big Pharma to come down from tower-

ing bioreactors to lay-flat bags with rocking motion as the manufacturing

equipment. This caused the proliferation of 3D technologies. The stirring bag

bioreactors were first introduced by Thermo Fisher's Single-Use Bioreactor

(SUB), developed as a result of cooperation between Baxter and Hyclone

and currently the market leader; this and the XDR-Disposable Stirred Tank

Bioreactor from Xcellerex were the only such systems available initially. This

was followed by the Nucleo bioreactor (ATMI Life Sciences), the BIOSTAT

CultiBag Stirred (STR) (Sartorius Stedim) (

Figure 5.5

), the Mobius CellReady

bioreactor (EMD Millipore/Applikon) (

Figure 5.6

), and the CelliGEN BLU

Single-Use Bioreactor.

Xcellerex Bioreactor

The nonstirring type 3D reactors include Sartorius-Stedim's SuperSpinner D

1000, which is noninstrumented; its aeration comes from hollow fiber mem-