Biomedical Engineering Reference

In-Depth Information

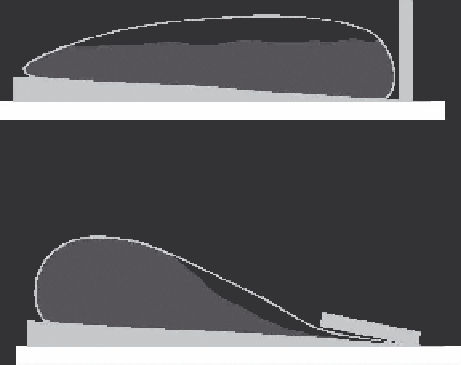

FIGURE 4.1

MayaBio PedalMixer mixing system.

sterilized, likely by filtration, it is not necessary to use any special

proprietary mixing system. An off-the-shelf plastic drum with a PE

liner and industry-standard mixers can do the job well at a fraction

of the cost. It is not necessary to use any proprietary liners as long as

the user is able to qualify a supplier; at this stage, the qualification is

relatively simple. Since all of unit operations in a cGMP operation are

validated, once a system has been qualified, it can be used repeatedly.

• Open mixing of media and buffer may be provided with a lami-

nar hood in those environments where there is a risk of cross-

contamination to reduce any additional burden on filter systems.

• The mixing systems available today are the same as used in dis-

posable bioreactors: in some instances the platform can be used for

both operations.

• While many reputable suppliers have developed highly sophis-

ticated 3D systems, these are not necessary for buffer and media

preparations; the cost of 3D bags with built-in stirring systems can

be prohibitive.

• The 2D bags offer many advantages including the ease of storage

because they are horizontally expanded; the wave motion created

inside these bags is extremely efficient.

• The newest entry in mixing technology, which is from MayaBio,

makes it possible for users to use any generic bag for mixing, further

reducing the cost as well as reducing the dependence on a propri-

etary supplier of components.