Biomedical Engineering Reference

In-Depth Information

• Bio-Pak

®

XL & XLPlus Bio-Containers are an efficient, lightweight,

and cost-effective alternative to large tanks and totes for sterile fluid

containment and processing. The single-use Bio-Pak

®

XL bags elimi-

nate the issues surrounding cleaning validation, storage, and steril-

ization of traditional bio-containers.

• Contour Tank Liners are a cost-effective alternative to dedicated

tanks and totes. Contour liners reduce cleaning validation and ster-

ilization of traditional containers. Most importantly, because they

are single use, the potential of cross-contamination between differ-

ent products is reduced.

• Bio-Pak

®

Totes are application-designed mobile totes mounted on

durable, nonmarking wheels. These stainless steel totes hold the

flexible bag plus outlet tubing in a self-contained, wheeled unit that

can be safely transported by forklifts. A unique bottom outlet sys-

tem allows fast flow rates and minimal container holdup volume.

• Freeze-Pak™ Cryogenic Bio-Containers are designed for use in cryo-

genic temperature applications under liquid nitrogen conditions,

and are used predominately for clinical and research applications.

The Freeze-Pak™ cryogenic film is a single-web polyolefin mono-

layer of 12 mil thickness and is preferred based on the film's perfor-

mance during the freeze-thaw process.

Applied Bioprocessing Containers (

http://www.appliedbpc.com

)

• Small volume containers, 50 mL to 20 L, with integrated handle, inte-

grated hanging capability, and needle-free sampling port, which may

be used with a sterile welder and is available as a manifold system.

• Containers for cylindrical tanks, 50 L to 750 L, 2D and 3D designs,

top or bottom drain, and available as a liner, fit most cylindrical

tanks and is available as a manifold system.

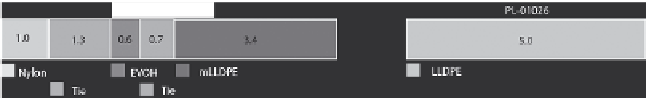

Disposable bags are made from plastic films (Chapter 2), whose composi-

tion is determined by the need for robustness, performance, and often the

size of the container. These bags have multiple layers for strengthening the

walls. Given in the following is the construction of ASI's typical bag design

(Figure 3.1):

PL-01077

PL-01026

1.0

1.3

0.6

0.7

3.4

5.0

Nylon

EVOH

mLLDPE

LLDPE

Tie

Tie

FIGURE 3.1

Layers of plastics in PL-01077 bag film offered by ASI.