Environmental Engineering Reference

In-Depth Information

3.3 Results and Discussions

There was no policy existent in the state of Uttar Pradesh (UP) for the promotion

of renewable energy source based power generation at the commencement of the

project in year 2001. Due to this lack the paper industry suffered from the imple-

mentation of emission reducing technologies. At the time of the project activity,

71 paper mills were operating in the state of UP. 94% of the power required for

the paper mills was provided through the state grid or from captive diesel genera-

tor sets producing high GHG emissions. There were hardly any rice husk based

cogeneration units in the state of UP in year 2001. This project activity is first of

its kind in the state of UP using only rice husk as a fuel. Thus the project clearly

demonstrates an opportunity to introduce the practice and also reduce GHG emis-

sions.

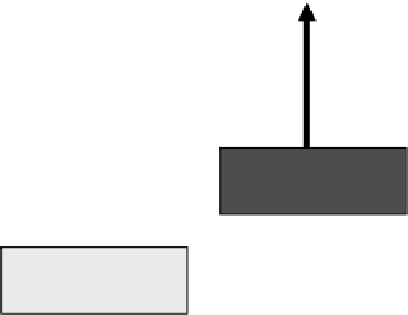

Emissions

Sequestered

Biomass Source

Biomass Storage

Biomass fired

boiler

Emissions

Generated

Auxiliary

Consumption

Electricity and

Steam Generation

Electricity and

Steam to Plant

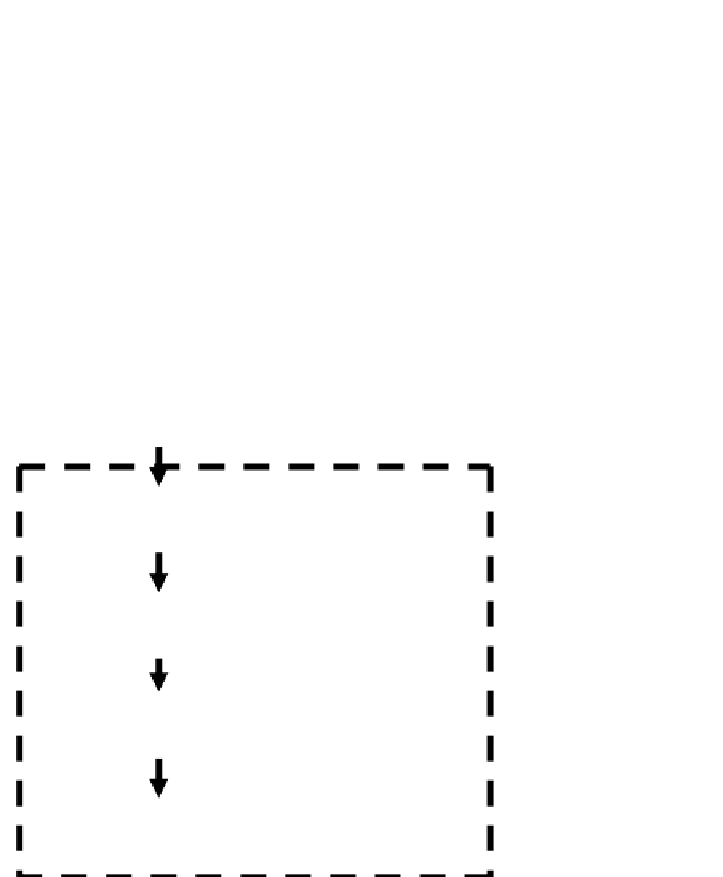

Fig. 3.1.

Project boundary represented by the dashed line

The project activity has replaced the fossil fuel consuming diesel generators with

carbon neutral rice husk to generate power. The CO

2

emitted by the project is

from biomass combustion and hence, being part of the global carbon cycle, does

not contribute to global warming. This is a distinct advantage of biomass-based

energy production.

SO

2

emissions of the project were less then the emissions from coal and oil

power plants, which is due to the very low presence of sulphur in rice husk. Simi-

larly NOx emissions were also less compared to coal and oil power plants. This is

Search WWH ::

Custom Search