Environmental Engineering Reference

In-Depth Information

and transporting the ashes. Nevertheless, the development of a blend using lower

quantities of this material could be feasible.

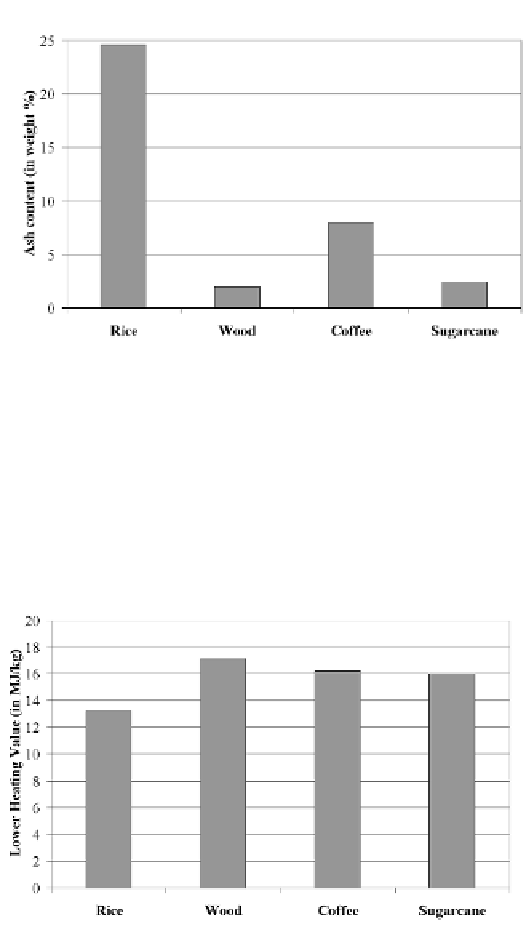

Fig. 2.3.

Ash content (water free) for different types of residues

The lower heating value shown in

Figure 2.4

was used to define how much energy

is generated per amount of dried biomass. Rice husks presented the lowest heating

value. This was due not only to its high ash content (

Figure 2.3

)

, but also due to its

low quantity of elementary carbon (36.5%) and hydrogen (6.3%) compared to the

other biomass. In contrast,

Eucalyptus sp.

wood presented the best heating value.

This was due to its low ash content (

Figure 2.3

) and high quantity of elementary

carbon (46.9%) and hydrogen (8.1%) in water free conditions.

Fig. 2.4.

Lower heating value for different types of residues

The ash melting point has a direct effect on the slag formation. Furthermore, the

melting of ashes at low temperatures may cause corrosion in the furnaces. As

shown in

Figure 2.5

, rice husks have a comparably low ash melting point. This al-

lied to its high ash content limited the use of this residue in the biomass mixtures.

Search WWH ::

Custom Search