Biomedical Engineering Reference

In-Depth Information

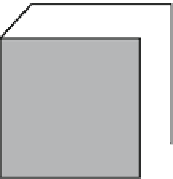

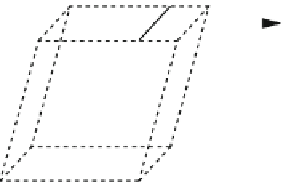

Fig. 7.3

A block subject to

shear stress that distorts the

shape in a way that its

cross-sectional area changes

from a

square

to a

parallelogram

L

A

T

L

i

f

e

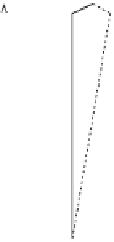

Fig. 7.4

Torque of force

T

applied to a cylinder fixed

on the

bottom

r

T

h

magnitude, i.e.,

T

f

s

, and in the opposite direction, as shown in Fig.

7.3

. The

shear stress is defined as

¼

T

/

A,

where

A

is the area of the surface. The magnitude

of the deformation is given by the shear strain, defined as

ε ¼ Δ

σ ¼

L

is

the horizontal dislocation of the surface that undergoes shear and

L

i

is the initial

height of the block, as can be seen in Fig.

7.3

.

The shear modulus,

S

, is given by:

L

/

L

i

where

Δ

T

A

ΔL

¼

σ

S

ε

¼

L

i

:

(7.5)

(block inclination

measured in radians). Observe that the shear force is always parallel to the area

A

.

The values of the shear modulus of some materials are given in Table

7.1

.

Generally, the value of

S

is between

Y

/2 and

Y

/3, meaning that it is easier to deform

solids with shear stress than with tensile or compressive stress.

Another type of stress is the torsion stress that can cause a deformation similar to

that produced by shear stress. In the case of shear, the force is applied parallel to the

area

A

, while in the case of torsion, the torque is applied in the direction of rotation.

In this case,

the shear strain

ε ¼ Δ

L

/

L

i

¼

tan

ϕ ϕ