Biomedical Engineering Reference

In-Depth Information

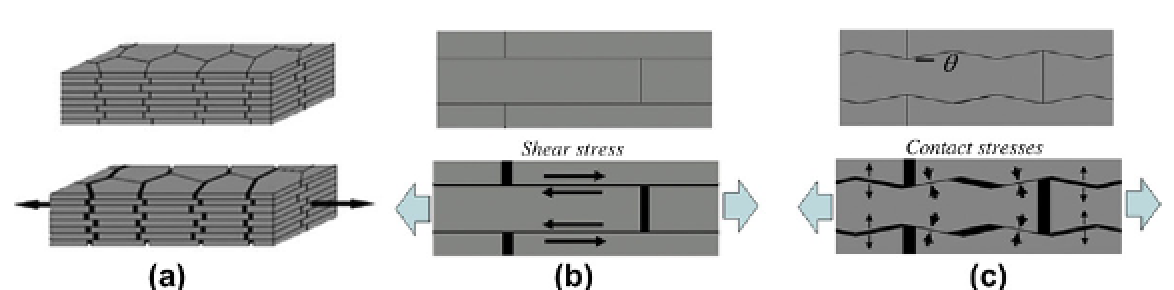

FIGURE 3.6

(a) Schematic of progressive tablet sliding in staggered composites. Load-transfer mechanisms in (b) flat

tablets and (c) wavy tablets (

θ

is the dovetail angle).

approaching the theoretical strength of the

material. Interestingly, the size of mineral inclu-

sions in hard biological materials like bone and

tooth is on the same order

[36, 37]

. This suggests

that nanometer inclusions in these materials

maximize their fracture resistance.

Although in nacre the tablets are in the

micrometer range, their small size still confers

on them high strength. For example, Bekah

et al

.

[30]

found that the aspect ratio must be small

enough so that an assumed edge crack extend-

ing halfway through the tablet is prevented

from propagating further. This condition is

given by:

improving the load transfer in biomimetic

materials.

3.2.5 Size Effects

In staggered composites, the flow of stress is

such that the interfaces are under shear while

mineral inclusions are under tension (tension-

shear chain). Therefore, the mineral inclusions

should resist high levels of tensile stress in order

to prevent brittle fracture. Brittle materials are

sensitive to initial flaws, which, for example,

include organic molecules embedded in the

mineral crystals during the biomineralization

process

[34, 35]

. These organic molecules are

much softer than the mineral and act as cracks

within the material.

For a cracked brittle inclusion, the condition

for failure is governed by the Griffith criterion:

ρ<0. 56

K

IC

(3.7)

τ

S

√

T

,

where

K

IC

is the mode-I fracture toughness of

the tablets. This expression suggests that by

decreasing the thickness of the tablets, the maxi-

mum allowable aspect ratio in the structure

increases. Increasing the aspect ratio is desirable

because it improves the performance of materi-

als with staggered structure, as indicated by

Eqs.

(3.1)-(3.3)

.

Bekah

et al

.

[30]

also argued that junctions in

the staggered composites act as crack-like

features when the material is loaded in tension.

Thus, decreasing the tablet thickness results in

a decrease in the size of these crack-like fea-

tures and therefore decreases the resulting

stress-intensity factor

K

I

. Computing this

γ

S

E

M

H

,

σ

F

M

=

α

E

M

φ

,

φ

=

(3.6)

where

σ

F

M

is the fracture strength of the mineral,

γ

S

is the surface energy,

h

is the thickness of the

mineral tablet, and the parameter

α

depends on

the geometry of the crack. Based on the Griffith

criterion, Gao

et al

.

[26]

showed that the strength

of the inclusions increases when they are made

smaller, because they can only contain small

defects. In theory, inclusions smaller than a

critical size of 30 nm

[26]

have a strength