Biomedical Engineering Reference

In-Depth Information

Al

2

O

3

, however, can also be grown with

plasma-assisted ALD. Here, the second precursor

is not water but oxygen plasma, produced

in situ

and which, due to the oxygen radicals produced,

shows enhanced reactivity toward TMA and

allows a lower processing temperature. The

quality of the coating may also be improved,

since the radical species tend to react more

vigorously with the ligands of the precursor or

the reaction byproducts and remove those from

the film. The plasma-assisted ALD, however,

requires more complex instrumentation and is

often not as easy to handle as thermal ALD. In

addition, the reacting species may sometimes

have a deleterious impact on the substrates,

particularly when those are polymeric. Also, due

to the shorter lifetime of the radical species,

coatings of deep pores and trenches may not be

as conformal as the corresponding thermal ALD

processes, since the radicals may quickly

recombine even before reaching the bottom of

such pores and trenches. Nevertheless, the

plasma-assisted ALD processes show good

promise for coatings at lower temperatures,

especially if metal coatings are required or the

chemical purity of the coating is of importance for

the anticipated application

[10]

.

From the chemical point of view, two general

cases may be differentiated. In the more com-

mon case, ALD will result in the growth of inor-

ganic materials, such as metal oxides, nitrides,

sulfides, or even metals

[9]

. This is simply

dependent on the selection of the precursors and

the thermal budget. In the currently less com-

mon case, organic molecules are used as precur-

sors. The move to reactive organic molecules

allows the layer-by-layer growth of polymers.

To differentiate these two growth processes,

the organic ALD is called

molecular layer deposi-

tion

(MLD). The first examples of MLD showed

the deposition of polyamides by alternating

injection of organic acid chlorides and amines

[11]

. The homo-bifunctionality of the molecules

used ensured that the growth was self-limiting.

More recently, the MLD was combined with

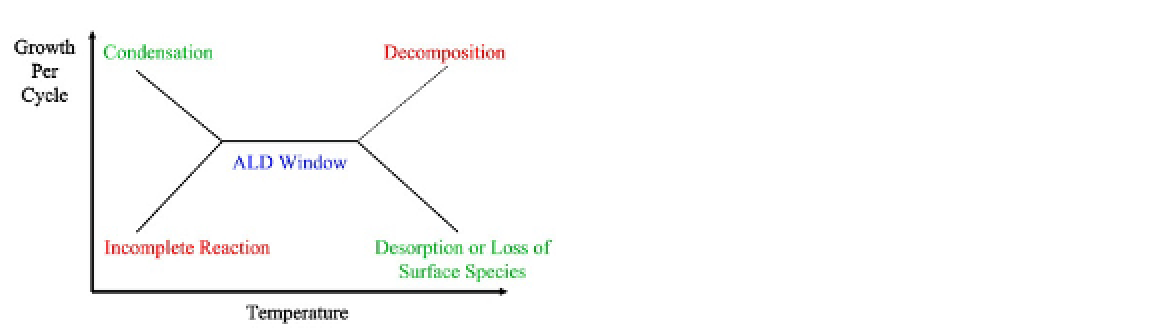

FIGURE 16.3

Schematic of the relation of the ALD

growth per cycle versus temperature. The scheme shows the

ALD window with possible scenarios for exceeding the tem-

perature limits at the lower and upper ends. Reprinted from

Ref.

5

. Copyright © 2010, with permission from the American

Chemical Society.

substrate due to the enhanced thermal budget.

Therefore, the ALD process is self-limiting and

reproducible only in a certain temperature range

for a particular pair of precursors. However,

within this range the growth is reproducible, and

the self-limiting nature is based on the interface

chemistry only.

16.1.3 Chemistry of ALD Processes

The chemistry involved in ALD is in most

cases based on simple chemical reactions such

as hydrolysis. In a few cases, the reactions are

redox reactions or condensation reactions. Tech-

nologically, most of the ALD processes can be

described as either thermal ALD, which is the

most common case as described thus far, or

the plasma-enhanced or plasma-assisted ALD,

where the second precursor is pushed toward

higher reactivity by generating a plasma

[5]

.

For thermal ALD of an Al

2

O

3

coating

[9]

, a

common first precursor is trimethylaluminum

(TMA), which is a highly volatile and pyrophoric

compound, and the second precursor is water.

The pair of precursors reacts to produce Al

2

O

3

and the growth can be easily controlled in a tem-

perature window between 100 °C and 300 °C.

Each cycle adds approximately 1 Å of Al

2

O

3

on

top of the substrate.