Biomedical Engineering Reference

In-Depth Information

15.3 CHEMICAL VAPOR

DEPOSITION

products and transport of reaction products

away from the surface. The main CVD process

parameters--such as temperature, pressure,

reactant gas concentration, and total gas flow--

require accurate control and monitoring. The

chemical reactions include pyrolysis, oxidation,

reduction, hydrolysis, or a combination of these

and may be catalyzed by the substrate. The

actual chemical reactions determine the operating

temperature range.

CVD is a well-established technique for the

deposition of metallic, ceramic, and semicon-

ducting thin films because it offers the advan-

tages of a relatively simple apparatus, excellent

uniformity, high density, high deposition rate,

and amenability to large-scale production. CVD

is a more complex method of forming thin films

and coatings than PVD. CVD exhibits several

distinct advantages, such as the capability of pro-

ducing highly pure and dense films or fine par-

ticles at reasonably high deposition rates and the

capability of coating surfaces of complex shapes.

Many forms of CVD are in wide use and are

frequently referenced in the literature. These

processes differ in the means by which chemical

reactions are initiated (e.g., activation process)

and process conditions

[4]

. As such, atmos-

pheric-pressure CVD, low-pressure CVD, and

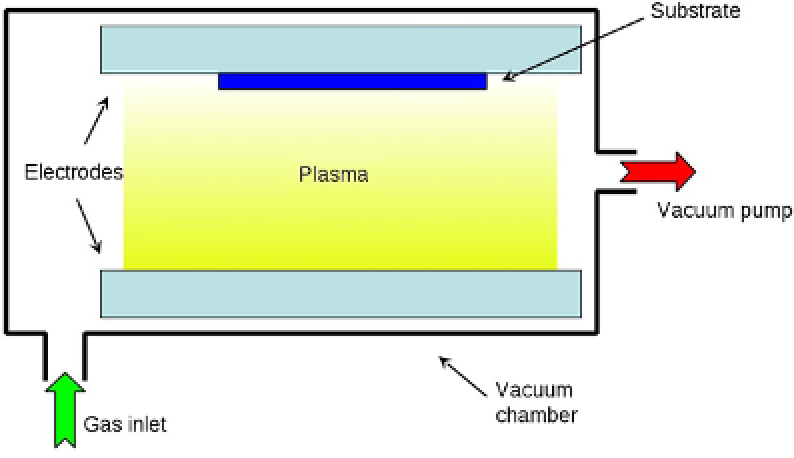

Chemical vapor deposition

(CVD) involves either the

dissociation of a gaseous chemical and/or chemi-

cal reactions between gaseous reactants when

heated, irradiated by photons, or subjected to a

plasma

[24]

. As a product, a thin film is deposited

on a surface. This technique is used to produce

very pure high-performance solid materials.

Depending on the activation sources for the

chemical reactions, the deposition process can

be categorized into thermally activated, laser-

assisted, or plasma-assisted CVD. The CVD pro-

cess occurs in a vacuum chamber, with pressures

ranging from the atmospheric pressure (atmos-

pheric-pressure CVD) to below 10

−

8

Torr (ultra-

high-vacuum CVD).

Figure 15.8

represents a

typical plasma-assisted CVD system.

The main steps that occur in a typical CVD

process can be summarized as follows

[14]

:

(1) transport of reacting gaseous species to the

surface of a substrate, (2) adsorption of the

species on that surface, (3) heterogeneous surface

reaction catalyzed by the surface of the substrate,

(4) surface diffusion of the species to growth

sites, (5) nucleation and growth of the film on the

substrate, and (6) desorption of gaseous reaction

FIGURE 15.8

Schematic of a plasma-assisted chemical vapor-deposition system.