Biomedical Engineering Reference

In-Depth Information

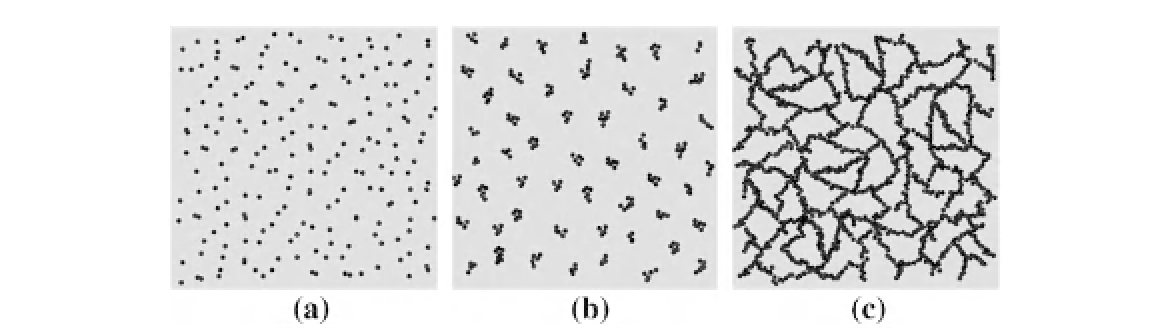

FIGURE 14.7

The three main stages of molecular sol-gel chemistry. (a) Solution stage: Partly hydrolyzed and condensed

molecular precursor species forming dimers and trimers (black dots). (b) Sol stage: Dimers and trimers agglomerate into

larger oligomers/nanoparticles. (c) Gel stage: Oligomers/nanoparticles further cross-link into an interconnected solid

network.

processing sol-gel compounds into desired

structures. To successfully transform the sol into

thin films, fibers, or monoliths or to infiltrate it

into template structures to create high-fidelity

ceramic replicas, gelation and formation of the

interconnected particle network need to be

slowed. This prevents premature solidification

and/or uncontrolled precipitation of the sol-gel

compound. In general, gelation kinetics depends

on similar parameters, as previously discussed

for the hydrolysis and condensation reactions.

Separating these processes is very difficult.

For templating applications, the most success-

ful approach is to dilute the sol either during or

immediately after the initial hydrolysis and con-

densation steps with low-boiling-point alcohols

(methanol, ethanol, isopropanol). Lowering the

colloidal particle concentration slows cross-link-

ing and allows template infiltration to be sepa-

rated from the gelation and solidification

processes. After infiltration of the template struc-

ture, alcohol evaporates and thereby slowly con-

centrates colloidal particles in the sol, inducing

their agglomeration and cross-linking into an

extended solid network, as shown in

Figure 14.7

.

A disadvantage of this method is that large

amounts of solvent are introduced along with

the sol-gel compound into the void space of

the template structure, resulting in a highly

porous and crack-prone network after solvent

evaporation. This interplay between gelation

kinetics and sol dilution depends strongly on

the sol-gel compound. Finding the appropriate

balance between these competing considera-

tions is one of the most important steps for

successful replication of synthetic and natural

structures.

Finally, it should be noted that for some sol-

gel compounds such as titania, the hydrolysis of

precursors (as well as condensation and gelation

reactions) are so fast that dilution alone is not

sufficient to prevent premature cross-linking

and precipitation. In these systems, it is impor-

tant to convert precursor molecules into inter-

mediary species that are stable under processing

conditions (coating, molding, casting, etc.) and

need other stimuli (such as heat and catalysts)

to undergo polymerization reactions. In the case

of titania, this can be achieved by converting

titanium alkoxides into stable oxy-chloro com-

plexes under strong acidic conditions or into

organic complexes by reaction with trifluoro-

acetic acid

[42]

. These entities are stable under

room-temperature conditions and can be pro-

cessed in an alcoholic solution. At elevated tem-

peratures, these complexes then decompose and

convert into amorphous or polycrystalline

titania.