Biomedical Engineering Reference

In-Depth Information

10

reflective loss from glass is not as severe

as that from semiconductors, a

∼

4% opti-

cal reflection from each air-glass inter-

face could still degrade the performance

of optical devices, especially when mul-

tiple components are involved

[2, 33]

.

To generate transparent ARCs on glass sub-

strates, various bottom-up self-assembly tech-

niques have been exploited

[1, 3, 53, 60, 61,

137-142]

. For instance, layer-by-layer assembly

of polyelectrolyte or polyelectrolyte-colloid

multilayers has been demonstrated as an effi-

cient means of creating ARCs on glass

[2, 60,

138, 140]

. Unfortunately, traditional bottom-up

techniques suffer from low throughput and

incompatibility with standard microfabrica-

tion, limiting the mass production of practical

coatings. By contrast, the spin-coating techno-

logical platform enables scalable production

of transparent moth-eye ARCs with tunable

structural parameters on glass substrates.

As-fabricated

200

o

C for 6 h

8

6

4

2

0

400

600

800 1000 1200 1400 1600

Wavelength (nm)

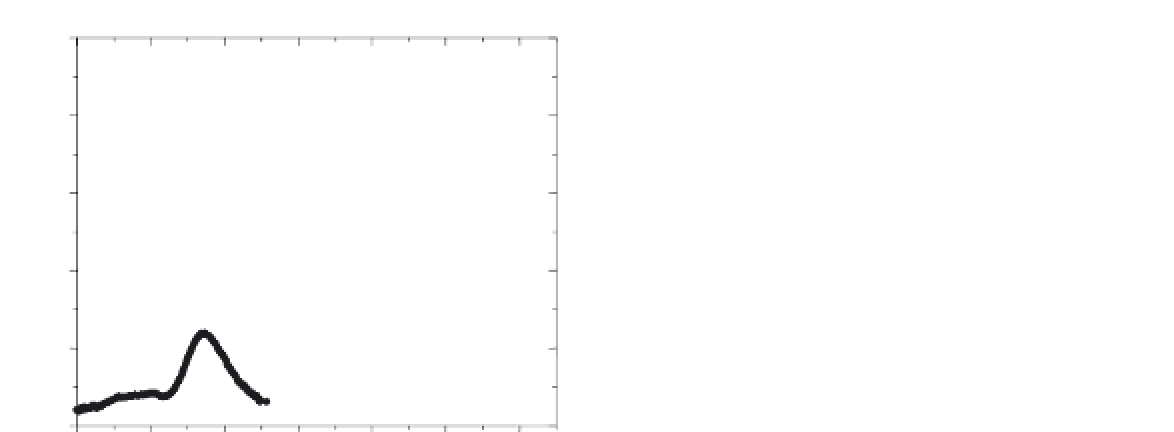

FIGURE 12.16

Comparison of the normal-incidence

specular reflectance between an as-fabricated GaSb moth-

eye grating and the same sample after annealing at 200°C for

6 h. Reprinted with permission from

Appl Phys Lett

92

(2008),

141109. Copyright 2008, American Institute of Physics.

concentrating solar cells and thermophotovoltaic

cells

[104, 108]

. The surface temperature of these

cells is usually higher than that of a conventional

cell

[134, 135]

. Therefore, ARCs with high ther-

mal stability are highly preferred. Fortunately,

the templated moth-eye ARCs exhibit excellent

thermal stability because the resulting coatings

are directly patterned on the wafer surface and

no foreign materials, as in conventional quarter-

wavelength design, need to be deposited on the

substrates.

Figure 12.16

compares the normal-

incidence specular reflectance spectra of a tem-

plated GaSb moth-eye ARC prior to and after

annealing at 200°C for 6 h. The change in reflec-

tance is very small. This is in sharp contrast to

the conventional quarter-wavelength ARCs that

exhibit significant antireflection degradation,

even at temperature as low as 100°C

[136]

.

12.4.1 Templated Polymer Moth-Eye

Antireflection Coatings

A schematic outline of the templating procedures

for fabricating polymer moth-eye ARCs on glass

is shown in

Figure 12.17

[100, 107]

. The polymer

matrix of spin-coated colloidal crystal-polymer

nanocomposites can be plasma-etched (40 mTorr

oxygen pressure, 40 sccm flow rate, and 100 W)

to adjust the height of the protruded portions of

silica spheres. The long-range periodic surface

protrusions of the exposed silica spheres can be

easily transferred to a poly(dimethylsiloxane)

(PDMS) mold. The solidified PDMS mold can

then be peeled off and put on top of ETPTA

monomer supported by a glass slide with spac-

ers in between. After polymerization of ETPTA

and peeling off PDMS mold, polymer moth-eye

nipple arrays with tunable depth can be easily

generated. The flexible PDMS mold enables the

creation of polymer moth-eye ARCs on both pla-

nar and curved surfaces.

12.4 TEMPLATED TRANSPARENT

MOTH-EYE ANTIREFLECTION

COATINGS

Transparent substrates, such as glass, are

widely used in our daily life. Although the