Biomedical Engineering Reference

In-Depth Information

Interestingly, arrays of

micro-candles

, consist-

ing of silicon columns as candle bodies and poly-

mer dots as candle wicks, are clearly evident

after removing the templating silica spheres

(

Figure 12.11

c). The polymer dots are unetched

residues of the thin polymer wetting layer (

∼

100

nm thick) between the spin-coated colloidal

monolayer and the silicon substrate. These dots

can be easily removed by brief oxygen RIE to

generate clean silicon pillar arrays (

Figure 12.11

d).

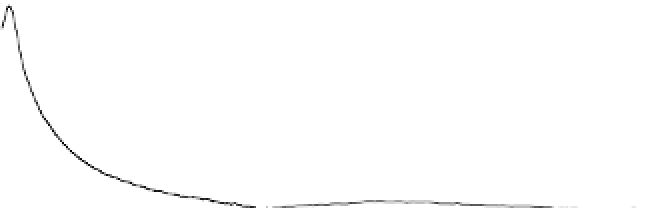

The resulting silicon moth-eye ARCs with

high aspect ratio show excellent broadband

antireflection properties, as illustrated by the

specular reflectance spectra shown in

Figure

12.12

. Very low reflectance (<2.5%) over a wide

range of wavelengths is obtained. The experi-

mental reflectance measurements are comple-

mented by theoretical calculations using the

RCWA. The experimental spectra match reason-

ably well with the simulated spectra.

Besides optical depth, the crystal structure of

the moth-eye ARCs also affects their antireflection

performance. As shown in

Figure 12.7

, the spin-

coating technology enables wafer-scale assembly

of non-close-packed colloidal crystals with meta-

stable square ordering. This allows us to create

moth-eye ARCs with square arrays using the

same templating technique described previously

and then compare their antireflection perfor-

mance with the nature-inspired hexagonal arrays

[110]

.

Figures 12.13

a and

12.13

b show side-view

SEM images of a square and a hexagonal moth-

eye array fabricated using the same templating

conditions. The antireflection performance of the

square array is apparently better than that of the

hexagonal array (

Figure 12.13

c).

The pillar pitch of moth-eye ARCs also affects

the final antireflection performance.

Figure

12.14

a shows a moth-eye ARC fabricated using

70-nm silica spheres (see

Figure 12.5

a) as tem-

plate.

Figure 12.15

b compares the specular reflec-

tion from a commercial crystalline silicon solar

cell with PECVD-deposited SiN

x

ARC, and the

templated nanopillar array

[106]

. It is apparent

60

Experiment Simulation

Si wafer

Si pillar array

50

40

30

5.0

2.5

0.0

400

600

800

1000

1200

1400

1600

Wavelength (nm)

FIGURE 12.12

Experimental (solid) and RCWA-simulated (dotted) specular reflection at normal incidence from a flat

silicon wafer and a 60-min Cl

2

-RIE-processed silicon pillar array. Adapted from Ref.

105

.