Biomedical Engineering Reference

In-Depth Information

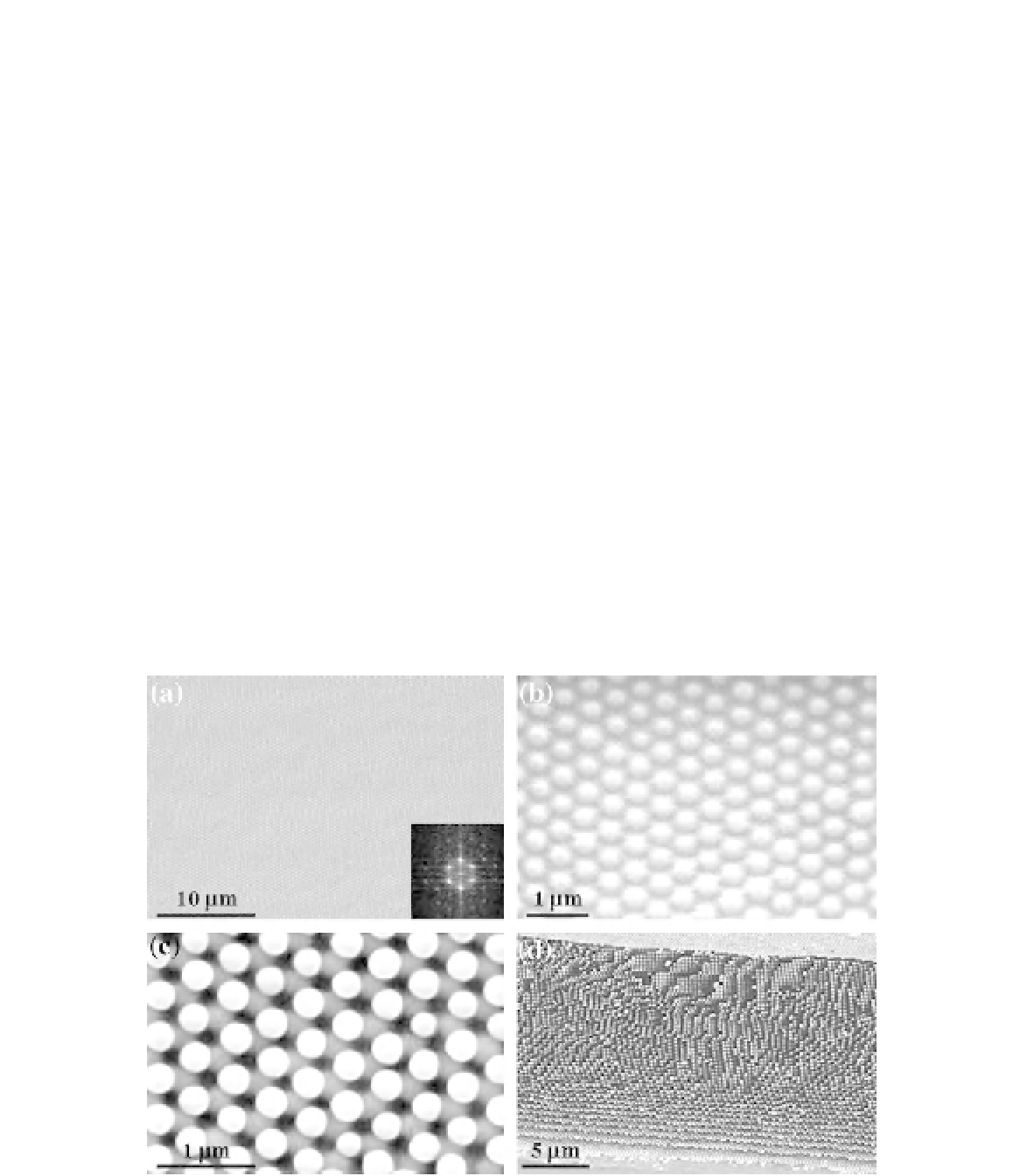

then rapidly polymerized to form 3D ordered

polymer nanocomposites (

Figure 12.2

). A scan-

ning electron microscope (SEM) image (

Figure

12.3

a) and its Fourier transform (inset of

Figure

12.3

a) demonstrate the highly ordered structures

with hexagonal packing on the film surface.

At higher magnification (

Figure 12.3

b),

another interesting feature is evident, i.e., the

spheres of the top layer are not contacting with

each other, but they exhibit center-to-center

distance around 1.41

D

, where

D

is the diameter

of colloids. The non-close-packing of colloids

and the specific spacing between intra-layer

spheres are much more apparent after the

polymer matrix is selectively removed by

conventional oxygen plasma etching. As shown

in

Figure 12.3

c, the top-layer spheres only fill in

the triangularly arranged crevices made by the

non-touching spheres of the underneath layer.

This non-close-packed structure is indeed

exhibited by all layers of the spin-coated

colloidal crystal. The ordering perpendicular to

the substrate surface is apparent in the cross-

sectional SEM image (

Figure 12.3

d).

Besides the unusual non-close-packed crys-

talline structure, the spin-coating technology

enables rapid production of wafer-sized colloi-

dal crystals with highly uniform and tunable

thickness ranging from a single monolayer to

hundreds of monolayers

[98, 99]

. The crystal

thickness can be easily adjusted by tuning the

spin speed and duration. The crystal thickness

is inversely proportional to the spin speed and

the square root of the spin duration. For instance,

colloidal crystals consisting of 325-nm-diameter

silica spheres with 2, 5, and 41 colloidal multi-

layers can be fabricated by spin coating at

6,000 rpm for 900, 170, and 120 s, respectively.

The typical spin-coating condition to assemble

submicrometer-sized particles into monolayer,

non-close-packed colloidal arrays (

Figure 12.4

)

is 8,000 rpm for 5-6 min.

FIGURE 12.3

(a) Typical top-view SEM image of a spin-coated colloidal crystal-polymer nanocomposite film. The inset

shows a Fourier transform of a 40

×

40

μ

m

2

region. (b) Higher-magnification image. (c) Typical top-view SEM image of a

released multilayer colloidal crystal after removing polymer matrix. (d) Cross-sectional SEM image of the released colloidal

crystal. Adapted from Ref.

98

.