Graphics Reference

In-Depth Information

Disc labeling do's and don'ts

It's important to label your work, but not all labeling is equally good:

•

Burn your CDs before you label them.

Chances are that the disc will not burn prop-

erly after the label is on.

•

Don't use tape, glue or pre-stick labels.

Most labels, including many laser-safe

brands, are made with an adhesive that eats away at the disc coating. Glue dries

out and loses its ability to hold, so labels will begin to curl, crack, or bubble.

Anything that isn't absolutely flat can ruin a CD player if it gets caught inside.

•

Don't send a disc without a sleeve or case.

CDs and DVDs may be long-lasting

media, but if you scratch them, they may not play.

•

For one-time disc printing, use a local or online service bureau.

There are many

short-run printers that specialize in disc duplication and printing. Use the same

company to print your disc sleeve or case insert as well and you should have con-

sistent color matching and an integrated presentation.

•

For multiple mailings, consider your own printer.

For about $100, you can buy a

color inkjet printer that has the ability to print directly onto a disc, as well as act as

your daily quick-print color option.

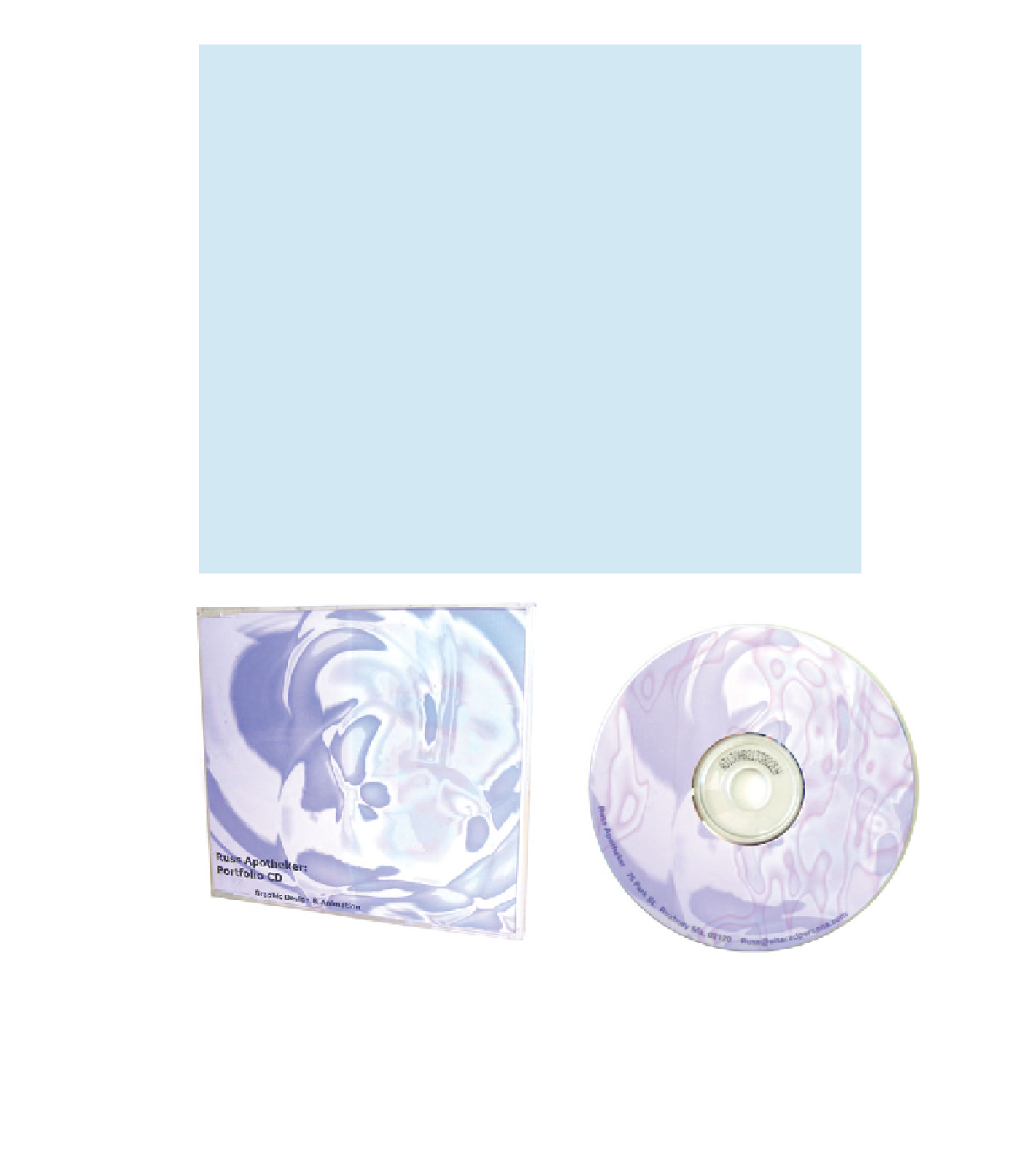

To raise the odds that your work will be viewed and retained,

your digital portfolio should be attractively packaged. At the

least, you should design a disc label. Even better is to add a

matching sleeve or case and a mailer insert.