Biomedical Engineering Reference

In-Depth Information

used; in other words, the polymeric solution is highly viscous. Viscosity can reach

2500 times that of water; however droplets are still being produced by the FFD. We

analyze next the behavior of highly viscous flows in FFDs, especially the alginate

solution, which viscosity has been described for in Chapter 2.

4.4.4.1 High-Viscosity Fluids in a MFFD

In this section we derive a relation between the flow rates and the driving pressures

of alginate and oil flow.

Model

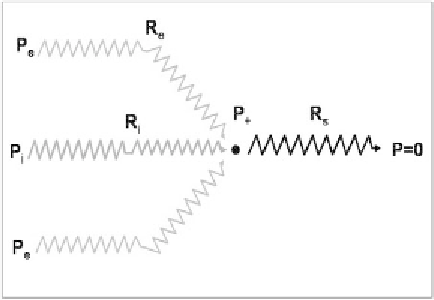

Using the notations of Figure 4.71 and the hydraulic resistances of each branch (

R

e

,

R

i

,

R

s

), the pressure drops in each branch can be written under the form

P

-

P

=

R Q

e

+

e

e

P P

-

=

R Q

(4.105)

i

+

i

i

P

=

R Q Q f Q Q

(2

+

) (

)

+

s

e

i

i

e

where

f

is a function of the ratio

Q

i

/

Q

e

, which takes into account the increase of

pressure drop due to the droplet flow in the outlet channel [39, 40]. We have made

the assumption that the pressure at the intersection

P

+

is not fluctuating much; this

assumption is justified by the experimental results. Denoting

q

*

=

Q

i

/

Q

e

and

p

*

=

P

i

/

P

e

, the solution of (4.105) is

*

p C

(

+

2) 2

-

*

q

=

*

(1

+

D p

)

-

R

e

C

=

(4.106)

R f

s

R

i

D

=

R f

s

Figure 4.71

Sketch of the hydraulic resistances of the different branches of the FFD. The indices

i

,

e

, and

s

, stand for internal (alginate) phase, external (oil) phase, and outlet.