Biomedical Engineering Reference

In-Depth Information

However there have been some flow models in special cases that we will present

later in this section. When facing considerable theoretical difficulties, an approach

based on nondimensional scaling numbers helps reveal the physical behavior.

Throughout this section we will use the scaling numbers characteristic of FFDs

already presented in Chapter 1.

Actuation of MFFDs

There are two ways of making the fluids circulate in a MFFD. The flows are either

driven by syringe pumps or by micropumps. In the first case, it is referred as flow

rate actuation; in the second case, it is referred as driving pressure actuation. In the

literature flow rate, actuation is more common because syringe pumps are largely

used in the laboratories. However, recently [71, 72] with the development of reli-

able pressure pumps, pressure actuation has started to be used, with the advantage

of very constant flow rates. It is common to make experiments keeping the ratios

q

*

=

Q

i

/

Q

e

or

p

*

=

P

i

/

P

e

constant. It is emphasized here that there is no equivalence

between theses two types of actuation: we shall see that, in the first case, the capil-

lary numbers ratio

Ca

i

/

Ca

e

=

h

i

Q

i

/

h

e

Q

e

—characterizing the flow behavior—depends on the

viscosity ratio

Ca

i

/

Ca

e

=

h

i

/

h

e

, while in the second case, the ratio

Ca

i

/

Ca

e

is

constant.

The Different Flow Regimes

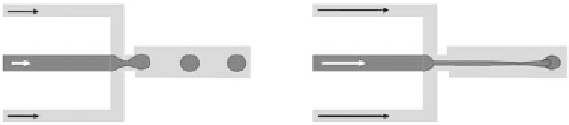

Two different categories of flow regimes exist in a FFD: dripping and jetting. Some

authors, according to their particular geometry of FFD, subdivide these two cat-

egories. In the dripping regime, the flow rates are small enough so that the drop-

let forms immediately after the nozzle. In the jetting regime, a thread or filament

stretches far into the outlet channel (Figure 4.68). In the first case, drops are larger,

with a small coefficient of variation (CV) of the order of a few percents. This is why

the dripping regime is preferred in biotechnology.

The dripping regime occurs at low values of the low rates. Upper limits of

this regime have been investigated in [73, 74]. It appears that two nondimensional

numbers pinpoint the transition to jetting regime: the critical Weber number

We

c

of

the dispersed phase, and the critical capillary number

Ca

c

of the continuous phase.

The first condition for a dripping regime is

2

ρ

U R

i

i

thread

(4.97)

We

=

<

We

c

γ

Figure 4.68

Dripping and jetting regimes. (a) Dripping regime: drops form at the nozzle; (b) jet-

ting regime: drops form at the tip of a long thread.