Geoscience Reference

In-Depth Information

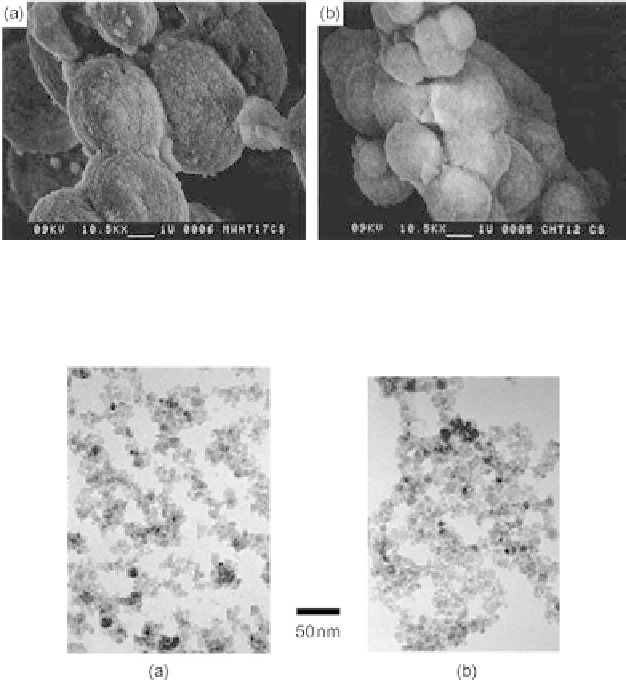

Figure 10.84 SEM photographs of CsAl

2

PO

6

[392]

.

Source: Courtesy of S. Komameni.

Figure 10.85 TEM images: (a) Co

1

2

x

Zn

x

Fe

2

O

4

and (b) Ni

1

2

x

Zn

x

Fe

2

O

4

nanoparticles

obtained using microwave-hydrothermal method

[395]

.

hydrothermal conditions is expected to lead to savings in energy and the cost of pro-

duction of these materials.

A majority of the experiments on microwave-hydrothermal processing are done

using a commercially available microwave digestion system, MDS-2000, which is

designed by the CEM Corporation, USA. This system produces a microwave fre-

quency of 2.45 GHz and the maximum pressure is

200 psi.

Komarneni et al.

[391]

have carried out the synthesis of BaTiO

3

,SrTiO

3

,

Ba

0.5

Sr

0.5

TiO

3

,BaZrO

3

,SrZrO

3

, PbZrO

3

,andPb(Zr

0.5

2Ti

0.48

)O

3

, using both conven-

tional and microwave-hydrothermal techniques. Conventional-hydrothermal proces-

sing, using TiO

2

B

xH

2

O gel and Sr(OH)

2

, usually yields platy, needles, or irregular or

subrounded agglomerated particles. However, microwave-hydrothermal processing

yields agglomerate-free, narrow particle size (0.1

μ

m) distribution with spherical

morphology, which is expected to have better sintering properties.

Tables 10.9 and

10.10

give X-ray diffraction (XRD) analysis of BaTiO

3

,SrTiO

3

,Ba

05

Sr

05

TiO

3

,

0.2