Geoscience Reference

In-Depth Information

(b)

Activated carbon

Activated carbon

grain

Activated carbon

grain

grain

(a)

10

10

μ

μ

m

m

2

μ

m

C

250

200

150

100

50

0

O

Ti

1

μ

m

0

100 200 300 400 500 600

(×1/100)

Energy (ev)

20

μ

m

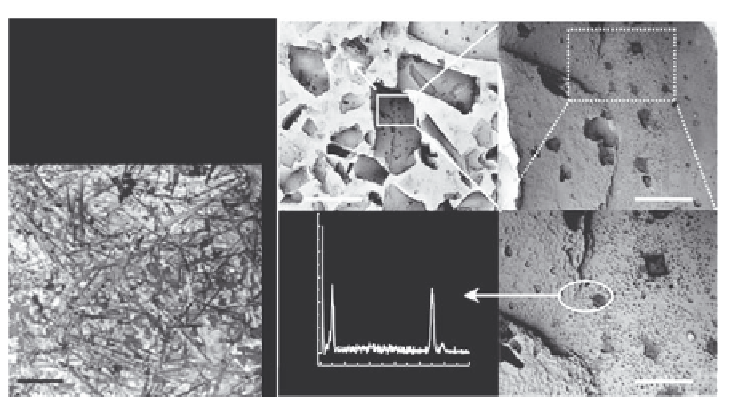

Figure 10.75 (a) ZnO:CNT and (b) TiO

2

:activated carbon

[19,339]

.

by 50

80 mesh. First activated carbon was washed with double distilled water

until the black color of washings disappeared, followed by soaking in 5% HCl solu-

tion with constant shaking for 24 h. Further, it was washed with distilled water till

the pH of washings became neutral. Finally, the product was dried at about 80

C.

Then a required amount of activated carbon (2 g) was taken in a Teflon liner con-

taining a desired amount (10 ml) of different molar concentrations of HNO

3

and

NaOH as solvents. The active metal oxides such as TiO

2

and ZnO were taken in

the form of respective oxides or gels. This mixture was stirred well using a mag-

netic stirrer for 2 h. Later, the Teflon liner was placed in an autoclave, which was

kept inside a furnace provided with a temperature programmer controller. The tem-

perature of the furnace was raised slowly up to a predetermined temperature

(150

200

C) for a period of 8

24 h. A.C:ZnO shows better catalytic properties

than A.C:TiO

2

.

Figure 10.75

shows the ZnO:CNT and TiO

2

:A.C composites

[19,339]

. However, the greatest disadvantage of these composites is the high cost

of activated carbon, but definitely, activated carbon:metal oxide

based composites

have been proven to be better photocatalysts than the pure metal oxides.

Recently, the authors

[338]

have reported the hydrothermal preparation of

Nd

2

O

3

-coated titania composite particles for photocatalytic applications. They

used 1 M NaOH at 250

Candpressure

80 bar with an experimental duration of

B

5

72 h. A different wt% of Nd

2

O

3

wasusedforthecoatinginordertorevealthe

role of Nd

2

O

3

. Highly monodispersed nanocomposite particles were obtained.

Figure 10.76

shows the schematic representation of the formation of Nd

2

O

3

-

coated titania designer composite particulates. Similarly, there are several reports

on the hydrothermal coating of functional materials on some ceramic supports.

For example, ZnO and TiO

2

nanoparticulates are coated on calcium aluminum sil-

icate beads as supports under hydrothermal conditions (

Figure 10.77

)with1M