Geoscience Reference

In-Depth Information

Figure 10.64 Mechanism of

HAp deposition on iron and

titanium plates

[321]

.

Dissolution

of iron

Fe + Ca(edta)

2

−

Ca

10

(PO

4

)

6

(OH)

2

Fe(edta)

2

−

, H

2

, OH

−

H

2

PO

−

, OH

−

H

2

edta

2

−

Ca(edta)

2

−

Ca

10

(PO

4

)

6

(OH)

2

Thermal

dissociation

Surface flaw formed by the

dissolution of iron

(a)

H

2

PO

4

, OH

−

H

2

edta

2

−

Ca(edta)

2

−

Ca

10

(PO

4

)

6

(OH)

2

Thermal

dissociation

Surface flaw formed by

polishing

(b)

c

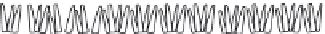

shows SEM photographs of the surfaces of titanium plates

coated with HAp (experimental

Figure 10.66a

conditions 0.05 M Ca(EDTA)

2

2

2

0.05 M

NaH

2

PO

4

solution at 160

C for 2 h) at pH (a) 4, (b) 5, and (c) 6.

Figure 10.67

represents SEMs of the surfaces and cross sections of titanium

plates after the second coating in 0.05 M Ca(EDTA)

2

2

2

0.05 M NaH

2

PO

4

solution

at 160

C for 4 h at pH (a) 6 and (b) 9. The first coating was carried out with a solu-

tion of the same composition at initial pH 5 and 160

C for 2 h

[321]

.

Thick films of HAp are also attempted for the use of gas sensors. There are sev-

eral varieties of HAp-based composites like HAp/bioactive glass composites, HAp/

polymer composites, and HAp/HAp (whiskers). Among the commonly used organ-

ics for HAp/polymer composites are phosphorylated cotton fibers, polymeric sub-

strate, polymethyl methacrylate, and poly [bis (sodium carboxylatophenoxy)

phosphase]

[321]

.

A comprehensive study undertaken at the Tokyo Institute of Technology, Japan,

under the leadership of Prof. M. Yoshimura, has moved HAp whisker-reinforced

HAp (HAw/HA) composites closer to real-world use. Researchers have long eyed

HA implants as replacements for natural bone. The two materials share the same