Geoscience Reference

In-Depth Information

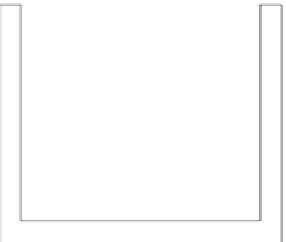

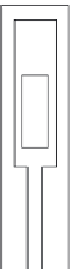

Figure 10.56 Electrolytic cell

assembly in the autoclave

[309]

.

Ag

Potentionstat

WE

RE2

RE1

CE

0.1

M

KCl

Ag/AgCl

(RE)

Liquid junction

0.5

M

A (OH)

2

(A = Ba, Sr)

Ti

Pt

Ti

(WE)

Pt

(CE)

0.5

M

A (OH)

2

(A = Ba, Sr)

regardless of the electrolysis conditions

[318]

. The preprocessed Ti substrate and

the platinum plate are suspended as the working electrode (anode) and the counter

electrode (cathode), respectively, by 0.5 mm diameter wires of the same metal as

the respective plates, keeping an interval of 30 mm between them in the electrolytic

cell containing 500 ml of the solution. The experiments were carried out at 150

C,

an approximate heating rate being 1.5

C/min. The Ti working electrode was polar-

ized potentiostatically from 50

C in the heating region to the end of the 150

C iso-

thermal region, keeping an anodic potential of

12.0 V versus Ag/AgCl. The

electrolysis current varies characteristically in the heating process and then remains

almost constant in the isothermal process. After the experiment, the Ti substrate

was washed in distilled water with an ultrasonic cleaner and dried at 120

C.

Kajiyoshi et al.

[29]

have also studied, in detail, the transport mechanism of film-

constituting elements. They propose two models: the first based on the principle

of tracer technique: (i) substitutional transport and (ii) interstitial transport. The sec-

ond is the short-circuit path model. The latter one is more appropriate here to describe

the mass transport in ATiO

3

(A

1

Ba, Sr).

Figure 10.57

illustrates schematically the

mass transport and film growth mechanisms of the short-circuit path model. In this

model, all the observed results can be explained comprehensively, together with an

atom-mixing mechanism accompanied by the dissolution

recrystallization process.

Figure 10.58

shows representative SEM micrographs of a fractured cross section of

5