Geoscience Reference

In-Depth Information

phosphor nanoparticles, because, the supercritical hydrothermal synthesis of these

phosphor nanomaterials is growing fast in recent years. Much of the literature data

on these materials deal with the other conventional methods like sol

gel, solid-state

reactions, melt, hydrolysis, and other wet chemical methods. As per the literature

survey data, the flow reactor is being used only by the authors' group to synthesize

nanoparticles of these materials.

10.6.11 Rare Earth Vanadates

YVO

4

:R

3

1

and GdVO

4

:R

3

1

(where R

Nd, Er, Eu) are known as efficient laser

host materials, excellent polarizer, and as a phosphor in its powder form

[210]

.

These compounds show high melting and no phase transitions. The synthesis of the

rare earth vanadates is popular by the conventional methods. The materials prepared

by these conventional methods encountered several problems like oxygen vacancies

resulting in major structural defects, presence of mixed phases in the products, and

loss of vanadium during crystallization leading to the loss of stoichiometry of the

product. In order to overcome these problems, the supercritical or near-critical

hydrothermal technique was proposed by Byrappa et al.

[211]

. There is only one

recent conference proceeding so far on the use of SCF technology (continuous flow

reactor) to synthesize rare earth vanadates on the whole in the literature. Both acidic

and basic solvents are used in the synthesis of yttrium and vanadium compounds,

which result in macro- and microcrystals. The addition of EDTA, or ammonium

metavanadate, into the system stunts the growth of larger particles and produces

nanoparticles of rare earth vanadates. The synthesis is normally carried out in the

temperature range 220

5

400

C.

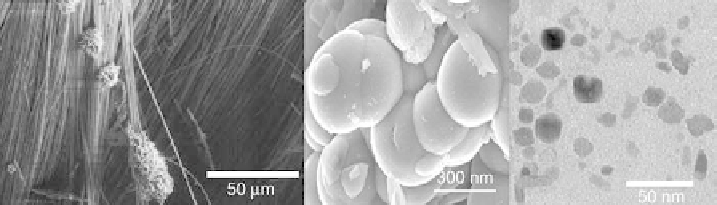

Figure 10.45

shows what the rare earth vanadates

produced under subcritical conditions. The use of SCF technology with a residence

time of 2.08 s yielded highly dispersed nanoparticles of GdVO

4

:Eu

3

1

with

10

15 nm size. NH

4

VO

3

, KOH, Gd(NO

3

)

3

, and Eu(NO

3

)

3

were used as the starting

materials with gluconic acid as a modifier to inhibit the particle aggregation.

Figure 10.46

shows the nanoparticles and nanostructures prepared using SCF tech-

nology. These results have shown a great potential for the synthesis of these materi-

als using SCF technology.

Figure 10.45 YVO

4

:Nd

3

1

nanostructures and nanoparticles.

Source: Photographs courtesy of K. Byrappa.