Geoscience Reference

In-Depth Information

The thinning down of the quartz plate depends upon the frequency measure-

ments and can be expressed as:

H

1

K

ð

MHz

μ

Þ

F

ð

MHz

Þ

5

e

ðμ

m

Þ

where e is the plate thickness, K is a constant characteristic of the material and of

its orientation, and F is the resonance frequency.

Sweeping is one of the most popularly used techniques in recent years to

enhance the performance of quartz resonators. Sweeping or solid-state electrolysis

or electro-diffusion is generally performed under a vacuum, or air, or hydrogen, or

desired atmosphere

[55

57]

. During sweeping, the crystal is placed in an electric

field and heated.

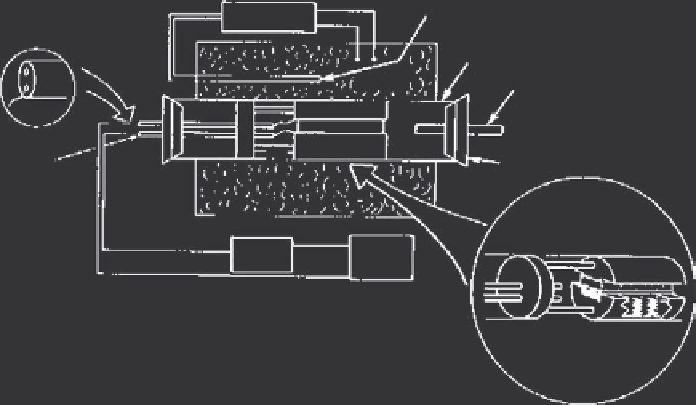

Figure 5.14

shows the schematic diagram of the sweeping appara-

tus. Then, there is a migration of the impurities, and some modifications are

induced within the crystal. According to the parameters used by the manufacturer

during the sweeping process, and the quality of the as-grown crystals, the results

could be very different. Sweeping reduces the formation of etch tunnels. The effect

of sweeping is to remove lithium and sodium deposited interstitially during growth.

These ions are usually trapped along an angstrom-wide tunnel, which is parallel to

the Z-axis in the quartz crystal lattice. In an interstitial position they interact with

aluminum impurities substitutional in the lattice to form Al

Li centers, which

have shown to be weakly bonded and are the cause of low radiation tolerance in a

resonator. In the sweeping process, these are replaced by Al-OH or Al-hole centers,

which have a much higher radiation tolerance.

Thermocouple

Temperatures

controller

Quartz tube

Gas inlet

Furnace

Plug

Gas outlet

High-

voltage

supply

Micro

Ammeter

Figure 5.14 Schematic diagram of the sweeping apparatus

[57]

.