Geoscience Reference

In-Depth Information

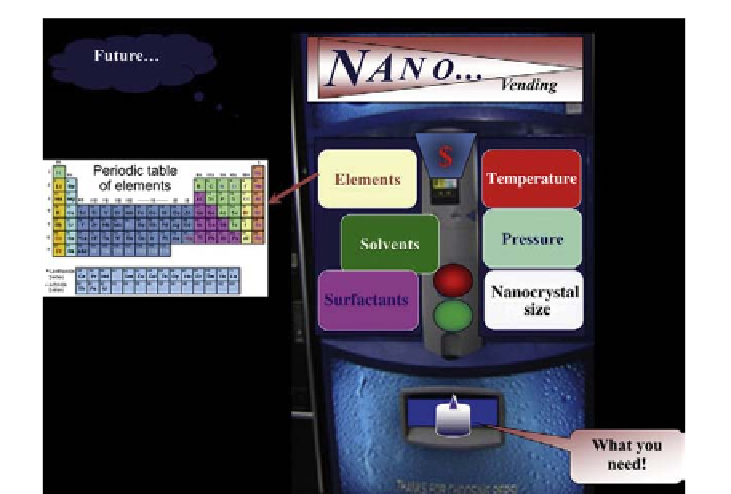

Figure 3.41 Nanovending machine for obtaining desired nanoparticles instantly with a

controlled size and shape

[1]

.

cells of 4 mm diameter and 6 mm height serve as the reaction vessels. However,

these high-pressure vessels are not very important for the growth of crystals and

processing of materials.

The progress in thermochemical computation, autoclave designing, multienergy

processing, and selection of an appropriate solvent and surfactant has led to the

materials processing at the speed of light or chemistry at the speed of light.

Accordingly, the researchers are visualizing the instant hydrothermal systems or a

new concept of nanovending machine to obtain instantly the desired nanoparticles

with a controlled size and shape

[1]

.

Figure 3.41

shows the materials scientist's

imagination for such a nanovending machine

[1]

. In fact, this would be the future

of hydrothermal technology with respect to nanotechnology.

3.6 Safety and Maintenance of Autoclaves

Safety is the prime factor in carrying out experiments under hydrothermal condi-

tions. It is estimated that, for a 100 cm

3

vessel at 20,000 psi, the stored energy is

about 20,000 J. Hydrothermal solutions—either acidic or alkaline—at high tem-

peratures are hazardous to human beings if the autoclave explodes.

Figure 3.42a

and b

show Stellite Tuttle cold-cone-sealed autoclaves and stainless steel acid

digestion bombs which ruptured at high pressure. Therefore, vessels should have