Geoscience Reference

In-Depth Information

8

13

7

BPT-3

12

6

11

5

4

A-A

3

9

2

1

10

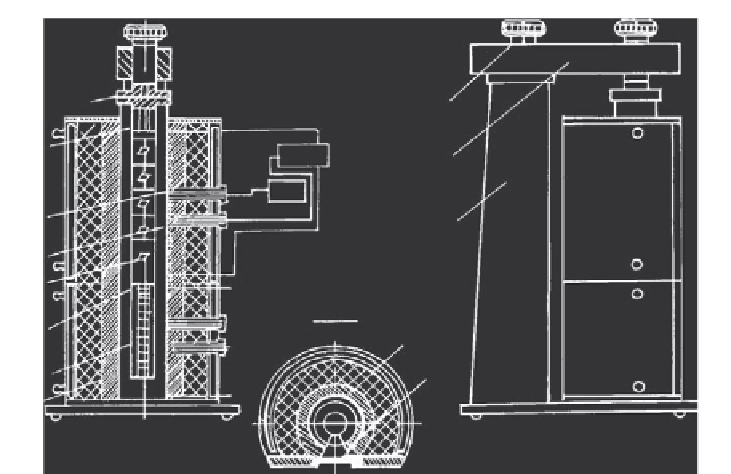

Figure 3.9 The schematic diagram of the visual autoclave

[7]

. (1) Quartz reactor, (2)

nutrient container, (3) baffle, (4) seed holder, (5) seeds, (6) Teflon tube, (7) solid cylinder,

(8) sealing disk, (9) heater, (10) thermocouple, (11) autoclave frame, (12) upper mount, and

(13) adjustable nuts.

glass has a very small coefficient of thermal expansion and hence the stresses

induced by temperature gradients are negligible. To make the quartz reactor tight, a

valve, which meets the following requirements, should be used:

i. The valve must be self-sealing, i.e., stress in the seal must grow as the pressure

increases, and no strong force that could damage the brittle reactor must be exerted on it

when sealed.

ii. The sealing material must be plastic; if so, the initial stress needed for self-sealing is low

and the reactor is safe.

iii. The valve must be chemically resistant with respect

to the chemical agents or the

solvents used.

The Teflon ring is placed in an annular groove whose diameter is greater than

that of the ring. Also, the ring's outer diameter will be greater than the inner diame-

ter of the reactor block. Hence, stresses appear in the ring due to its deformation,

and this is sufficient for the initial sealing.

The main advantage of quartz autoclaves is their high stability with respect to

an acid medium which permits us to use a condensed solution, i.e., the concentra-

tion of substance to be crystallized may be enhanced without increasing the temper-

ature. In this case, a considerable gain can be obtained for the processes which run

under lower temperature and lower pressure, which turns out to be cheaper and