Agriculture Reference

In-Depth Information

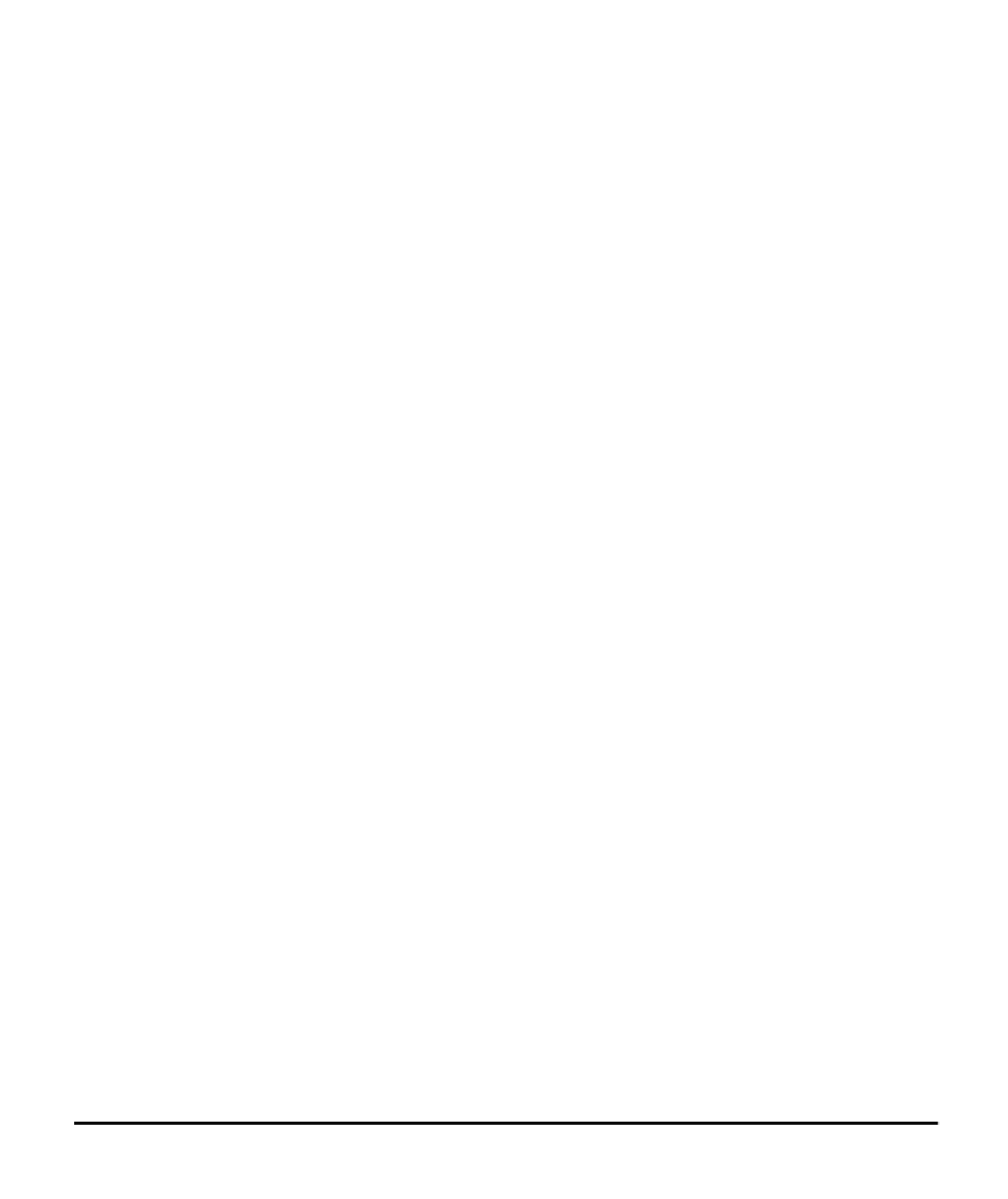

Table 31.5.

Effect of calcium chloride on quality attributes of 'Surkh' loquat during 10 weeks of storage

at 4

◦

C.

Soluble

Solids (

◦

Brix)

Titratable

Acidity (%)

Firmness

(kg force

1

)

Ascorbic Acid

(mg/100 g)

Weight

Loss (%)

Browning

Index (%)

Treatment

Control

11.41

0.40

1.01

2.59

3.20

18.72

CaCl

2

(1%)

12.19

0.41

1.11

2.85

2.98

18.15

CaCl

2

(2%)

12.49

0.38

1.18

2.93

2.70

15.79

CaCl

2

(3%)

13.10

0.41

1.20

3.12

2.57

10.58

LSD

0.14

0.03

0.05

0.26

0.29

1.61

1

One kg force

9.81 Newton force.

Source: Adapted from Akhtar (2009); Akhtar et al. (2010).

=∼

Composition and nutritional profile

Loquat fruit composition and nutritional profile is presented

in Table 31.2. Loquat is a low-calorie (47 kcal/100 g) fruit

and is rich in potassium and vitamin A; it delivers ap-

proximately 1,500 IU per 100 g (51% of RDA or rec-

ommended dietary allowance). The fruit is also high in

phenolic flavonoids, for example, protocatechuic acid, hy-

droxybenzoic acid, epicatechin, ferulic acid, feruloylquinic

acid, coumaric acids, and chlorogenic acid. Chlorogenic

acid concentration is the highest in fully ripe loquat. These

compounds potentially protect the lungs and oral cavity

from tumors (Takuma et al., 2008).

The bioactive compounds and antioxidant capacity of lo-

quat fruit have been reported widely in the literature such

as bioactive compounds (Xu and Chen, 2011), carotenoids

(Zhou et al., 2007; Faria et al., 2009), and antioxidant ca-

pacity or potential (Ferreres et al., 2009; Xu et al., 2010).

Both cardiovascular disease and cancer are assumed to be

the consequences of oxidative damage, which may lead to

mutilation of macrobiomolecules such as DNA, lipids, and

Table 31.6.

Summary of processed products made from loquat.

Product

Processing Method

Reference

Nectar/jam

Loquats without seed are cooked for 10-15 min and stirred, then sugar is

added and boiled for 1-2 min. Jam prepared with added pectin.

Ogonowski (2007)

Juice

Immobilized pectinase with chitosan is used for loquat juice clarification.

The immobilized enzyme is added to 50 g/liter juice (at pH 3.8, 50

◦

Cfor

2 hours). The immobilized enzyme hydrolyzes the pectin, thus separating

the sediment from juice. The juice is stable at cold temperature storage.

Zhigang et al. (2004)

Loquat and sugar are heated at moderate temperature (

∼

50

◦

-55

◦

C) for

10-15 min with occasional stirring. Puree is sieved using appropriate

mesh-size screen to a smoother finish and allowed to cool. Adjustment of

acidity is optional.

Puree

Ogonowski (2007)

Canned loquat

Fruit is pitted and packed in cans with syrup, and sealed cans are thermally

processed in a retort (pressure cooker).

Takahashi et al. (2000)

Fermented tea

Tea rolling process is used in producing fermented loquat tea by drying tea

leaves to a constant moisture, and then loquat leaves are added. The

rolling step kneads both of the leaves types together, followed by

fermentation and drying of the kneaded leaves.

Shii et al. (2011)

Seed powder

The loquat seeds are ground and pasteurized, followed by conventional or

freeze-drying.

Inoue (2008)

Search WWH ::

Custom Search