Agriculture Reference

In-Depth Information

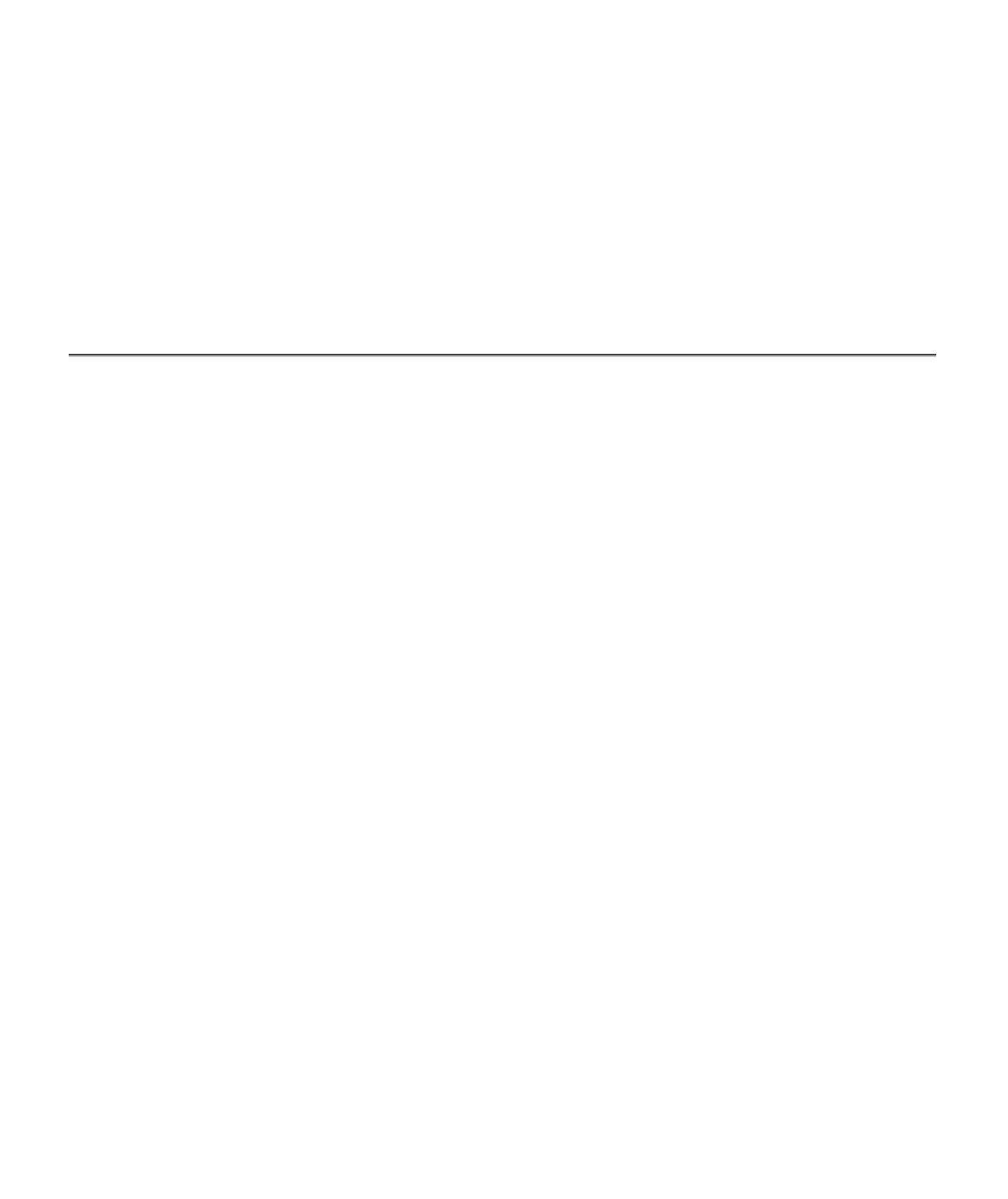

Table 31.1.

Physical and chemical characteristics of selected Indian jujube cultivars.

'Mundia

Murhra'

Characteristics

'Katha'

'Bagwari'

'Umran'

'Chhuhara'

'Illaichi'

'Karaka'

'Narma'

Yellow to

reddish

brown

Yellow to

reddish

brown

Yellow to

reddish

brown

Golden

yellow

Golden

yellow

Greenish

yellow

Greenish

yellow

Light

green

Appearance

Average fruit weight (g)

18.50

16.00

21.00

12.50

3.60

23.00

22.00

17.50

Pulp:stone ratio

25.00

13.30

19.60

11.30

24.80

—

16.70

12.90

Moisture (%)

74.33

77.92

77.81

76.42

73.97

86.60

88.13

79.30

Total soluble solids (

◦

B)

21.40

18.00

22.70

17.20

24.70

11.80

13.00

16.80

Acidity (%)

0.10

0.11

0.29

0.35

0.22

0.31

0.22

0.25

Reducing sugars (%)

4.54

5.94

4.38

3.72

3.91

5.88

4.00

3.70

Total sugars (%)

19.65

16.17

14.84

16.23

16.98

9.97

11.10

14.90

Source: Pareek (2001); Pareek et al. (2009).

to 100.3 mg CO

2

/kg/hr as the fruit entered the ripening

phase. Later, the rate of CO

2

production declined rapidly

as the fruit became overripe (such pattern of respiration

rates is typical of climacteric fruits). Singh et al. (1981)

observed that on average, the rate of respiration was 52.4 mg

CO

2

/kg/hr at the green stage and reached up to 127.64 mg

CO

2

/kg/hr at the red-ripe stage. The rate of respiration

among various cultivars at the red-ripe stage was found

to be 119.72 mg, 131.54 mg, 137.32 mg, and 133.33 mg

CO

2

/kg/hr in 'Umran,' 'Rashmi,' 'Kaithli,' and 'Ponda,'

respectively.

Indian jujube produces high amounts of ethylene and

shows responses to exogenous ethylene treatments as mea-

sured by changes in skin color, juice color, and compo-

sition (Pareek et al., 2009). Ethylene production was not

detected until the 12th week after anthesis. Thereafter,

ethylene production increased rapidly, reaching a maxi-

mum of 13.0

μ

l/kg/hr as the fruit entered the maturity

phase 18 weeks after anthesis and then declined rapidly.

The ethylene production rate in ripe jujube fruits is con-

sidered “high” according to the classification of Paull and

Duarte (2011).

Jujube fruit is susceptible to a number of postharvest

diseases; as during packaging, storage, and transport, fruits

may be exposed to various decay-causing microflora (Pa-

reek et al., 2009). Kainsa et al. (1978) reported that some of

the predominant organisms observed on freshly harvested

fruits were

Aspergillus niger, A. sydowii, Rhizopus oryzae,

Penicilium chrysogenum, Alternaria tenisima, Phoma

spp.,

and

Cuvrularia

spp., of which

A. niger

and

R. oryzae

caused

the greatest fruit spoilage.

Postharvest storage, treatment, and shelf life

The storage life of jujube fruits is extremely short and the

rapid perishability of the fruits is the main postharvest prob-

lem. The typical shelf life at ambient temperatures (

25

◦

C)

is 2-4 days. Due to the surplus of fruits in the local markets

during peak season, a substantial quantity goes to waste,

resulting in heavy postharvest losses (Pareek et al., 2009).

It is possible that the high rate of respiration and ethylene

production during jujube fruit ripening are responsible for

the short storage life under room temperature conditions

(Abbas, 1997).

Gupta and Mehta (1987) suggested that postharvest dip-

ping of fruits in cold water can effectively reduce respira-

tion, ethylene production, and enzymatic activities, whereas

hot water treatment controls the growth of pathogens,

thereby prolonging the shelf life and overall quality of

fruits. After harvest, dip treatments of 'Gola' jujube fruits

in cold water for 2 hours or keeping them exposed to air

for 4 hours improved their shelf life. Dipping fruits in

500 ppm thiabendazole, Captan, and Dithane M-45 im-

proved the shelf life by reducing respiration rate. Siddiqui

and Gupta (1989) reported that hot water (40

◦

C) dipping of

fruits has been reported to reduce transpiration and physi-

ological weight loss of fruits during storage. The hot water

dipping treatment may prevent surface molds from devel-

oping, resulting in a lower fruit loss due to decay.

Zhong and Xia (2007) reported that 1-methyl

cyclopropene (1-MCP) treatment in combination with chi-

tosan coating significantly improved the storage life and

quality of Indian jujube fruit at room temperature storage.

Ozone and potassium sorbate treatment has been shown to

∼

Search WWH ::

Custom Search