Agriculture Reference

In-Depth Information

In Brazil, two types of juice are manufactured: the clar-

ified juice called

cajuına

and the unclarified juice (Ctenas

et al., 2000). The unclarified juice has a strong and peculiar

flavor that is not pleasing to some consumers. It is usually

diluted with five parts of water, with sugar added according

to taste.

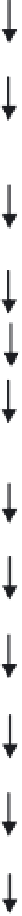

The juice processing steps are shown in Figure 29.4

(Tocchini et al., 1995). Homogenization is done principally

to reduce the juice particles to a uniform size and as small

as possible, avoiding rapid separation of phases during stor-

age. In the formulation, citric acid, sodium benzoate, and

sodium metabissulfite are added. Pasteurization is usually

accomplished by plate heat exchangers at 90

◦

C. After hot

filling and sealing, the bottles are conveyed to a cooling

unit and cooled to ambient temperature.

Concentrated juice, frozen pulp, nectar, ready-to-drink,

and sweetened concentrated juice were found to have

ascorbic acid contents of 13.7-121.7 mg/100 g and to-

tal carotenoid levels of 0.08-1.98 μg/g (Assun¸ ao and

Mercadante, 2003);

Raw cashew apples

Sorting

Washing

(chlorinated water)

Grinding

Extraction of juice

(continuous press)

Homogenization

(colloidal mill)

β

-carotene was the major carotenoid,

while

α

-carotene,

β

-cryptoxanthin, 9-cis-

β

-carotene, and

Formulation

13-cis-

-carotene were also present.

With the breeding advances to develop improved lines

of cashew, there has been a resurgence of research on the

cashew apple in recent years. Studies have been directed

mostly for optimization of processing, application of new

technologies, and new product and ingredient development.

In cashew apples processed by combined methods, pH

decreased while soluble solids and reducing sugars in-

creased (Souza Filho et al., 1999). Ascorbic acid decreased

23% after blanching (vapor at 100

◦

C for 2 min), 32% after

the first day of osmosis (sucrose syrup with the addition

of preservatives), 35% after the fifth day of osmosis, 69%

after the heat treatment (100

◦

C for 1 min), and 87% after

60 days of storage at ambient temperature (

β

Deaeration

Pasteurization

Hot-filling

Sealing of bottles

Cooling

28

◦

C).

Cashew apple juice was clarified by microfiltration after

enzymatic treatment to reduce astringency and improve per-

meate flow (Campos et al., 2002). Titrable acidity and pH

were not affected by the clarification process. Acidity and

soluble solids did not change during storage at room (30

◦

C)

and refrigeration (4

◦

C) temperatures, the range being main-

tained at 0.39-0.41 g/100 g (expressed as malic acid) and

6.4

◦

−

∼

Storage

Figure 29.4.

Flow diagram of the processing of

cashew apple juice.

6.9

◦

Brix, respectively. Total tannins (0.70 mg/100 g)

did not change significantly, but condensed tannins de-

creased after 60 days at ambient temperature. While the

color of the juice kept at refrigeration temperature did

not change, initial darkening was observed in the juice

kept at room temperature. Ascorbic acid decreased from

135 mg/100 g in the original pulp to 103 mg/100 g in the

clarified juice. After 60 days of storage, only 53.6% of this

vitamin was retained in the refrigerated juice; however, it

maintained its clarity, remained a source of vitamin C de-

spite the losses, and complied with microbiological safety

requirements.

Osmotic dehydration followed by air-drying or vacuum-

drying of yellow cashew apple was investigated by Falade

et al. (2003). The moisture content of osmosed cashew

apple

decreased

with

increasing

immersion

time

and

Search WWH ::

Custom Search