Agriculture Reference

In-Depth Information

Compositional changes during ripening

During ripening of acerola, water, sugars, and soluble solids

increase, while vitamin C and protein decrease (Carvalho

and Manica, 1994; Vendramini and Trugo, 2000; Nogueira

et al., 2002). Acidity was found to increase by Vendramini

and Trugo (2000) and to decrease by Carvalho and Manica

(1994).

In 12 genotypes, considerable variations were observed

in fruits of the same stage of maturity, the total phenolic

varying from 841 to 1,888 mg/100 g catechin equivalents

and the total carotenoid from 9.4 to 40.6

μ

g/g

β

-carotene

equivalents in the ripe fruit (Lima et al., 2005). Pheno-

lic degradation and carotenoid biosynthesis were noted

during ripening. The

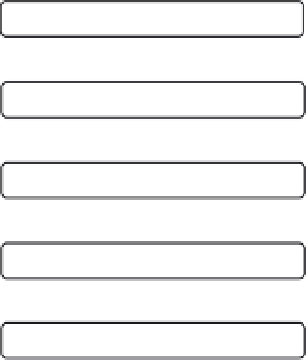

Harvesting

Transport to packing-house

Sorting

Washing

Freezing

-carotene increased two to three

times from the partially ripe to the ripe fruits in com-

mon and 'Olivier' acerolas (Porcu and Rodriguez-Amaya,

2006);

β

Packaging

-cryptoxanthin and violaxanthin also increased

significantly.

β

Storage

Possible health benefits

With the presence of vitamin C, carotenoids, and pheno-

lic compounds, bioactive substances associated with the

reduction of the risk of degenerative diseases (e.g., can-

cer and cardiovascular diseases), acerola may contribute to

the prevention of these diseases. This fruit was shown to

have tumor specific cytotoxic activity and multidrug resis-

tance reversal activity, suggesting possible application for

cancer therapy (Motohashi et al., 2004). Acerola extract

enhanced the antioxidant activity of soy and alfalfa phy-

toestrogen extracts in a variety of low-density lipoprotein

(LDL) systems (Hwang et al., 2001). Polyphenols isolated

from acerola (cyanidin-3-

α

-

O

-rhmanoside, pelargonidin-

3-

α

-

O

-rhmanoside, and quercetin-3-

α

-

O

-rhmanoside) pos-

sessed O

2

-scavenging activity and an inhibitory effect on

both

Marketing

Figure 29.2.

Flow diagram of the preparation of

frozen acerola fruits.

aged, spoiled, or fermented. Fruits with physical defects

cannot be used as raw material for frozen fruit but can be

utilized for frozen pulp or juice.

The fruits are washed by immersion in tanks with chlo-

rinated, cold water, which is constantly renewed. At the

tank's exit, water-jet washes remove excess chlorine.

The fruits are taken to freezing rooms or tunnels in con-

tainers that permit uniform passage of the cold air. Among

the different types of freezers available, the tunnel with

forced-air circulation has been shown to be very efficient

for the freezing of acerola (Bleinroth et al., 1996).

A flow diagram for the processing of frozen pulp and

juice is shown in Figure 29.3 (Tocchini et al., 1995; Manica,

2003). After washing and a second sorting to remove those

unfit for processing, the fruits are subjected to pulping to

separate the pulp from fibrous material, seeds, and skin, at

the same time reducing the particle size thus turning the

product more homogenous. A brush-type pulper is used

with a 1-mm dia mesh sieve. Any air incorporated during

pulping is removed by vacuum to minimize oxidation. The

pulp is cooled to approximately 5

◦

C, filled into drums lined

with double polyethylene bags, and sealed. Freezing is done

in a tunnel operated at -20

◦

C. The frozen pulp is stored at

thesametemperature.

α

-glucosidase and advanced glycation end product

formation in vitro (Hanamura et al., 2005). With its very

high vitamin C content, acerola can be utilized in pharma-

ceutical formulations or for the enrichment of foods.

Processing and processed products

In Brazil, acerola is now widely marketed as fresh fruit,

fresh and thermally processed juice, frozen fruit, frozen

pulp, or juices in combination with other fruits. It is also

used in ice creams, jams, jellies, desserts, and liquors. The

various steps involved in the preparation of the frozen fruit

are shown in Figure 29.2 (Alves et al., 1995; Bleinroth

et al., 1996; Manica, 2003).

In the packinghouse, the fruits on conveyor belts are in-

spected to remove those that are immature, overripe, dam-

Search WWH ::

Custom Search