Agriculture Reference

In-Depth Information

various disorders, such as cardiovascular complications,

cancer (colon, breast, prostate), and hypercholesterolemia

(Heredia et al., 2003). Chlorophyll and carotenoid com-

pounds are also present in green and turning-color table

olives. These pigments have considerable potential in pre-

venting damage to human health from mutations, includ-

ing cancer and other degenerative disorders (Bendich and

Olson, 1989; Dashwood, 1997; Mınguez-Mosquera et al.,

2008; Ferruzzi and Blakeslee, 2007).

Therefore table olives constitute a good source of healthy

compounds in the diet. Furthermore, table olives could

be used as a vehicle for incorporating probiotic bacteria

and transportating bacteria cells into human gastrointesti-

nal tract (Lavermicocca et al., 2010).

Preparation operations

*Olive harvesting

*Shipping

*Cleaning and washing

Milling

Mixing

OLIVE OIL

As stated before, olive oil is the main product derived from

olive fruits (90% of olive production). Olive oil is the oil

obtained solely from the fruit of the olive tree (

Olea eu-

ropaea

L.), to the exclusion of oils obtained using solvents

or reesterification processes and of any mixture with oils of

other kinds (IOC, 2010c). Olive oil is used throughout the

world probably due to its recognized nutritional properties.

Solid-liqu

id

separation

Selective filtration Pressure extraction

Centrifugation

Three Phases

Two Phases

*

Solid olive-pomace

* Solid olive-pomace

* Residual water

* Olive oil

* Olive oil

Olive oil processing

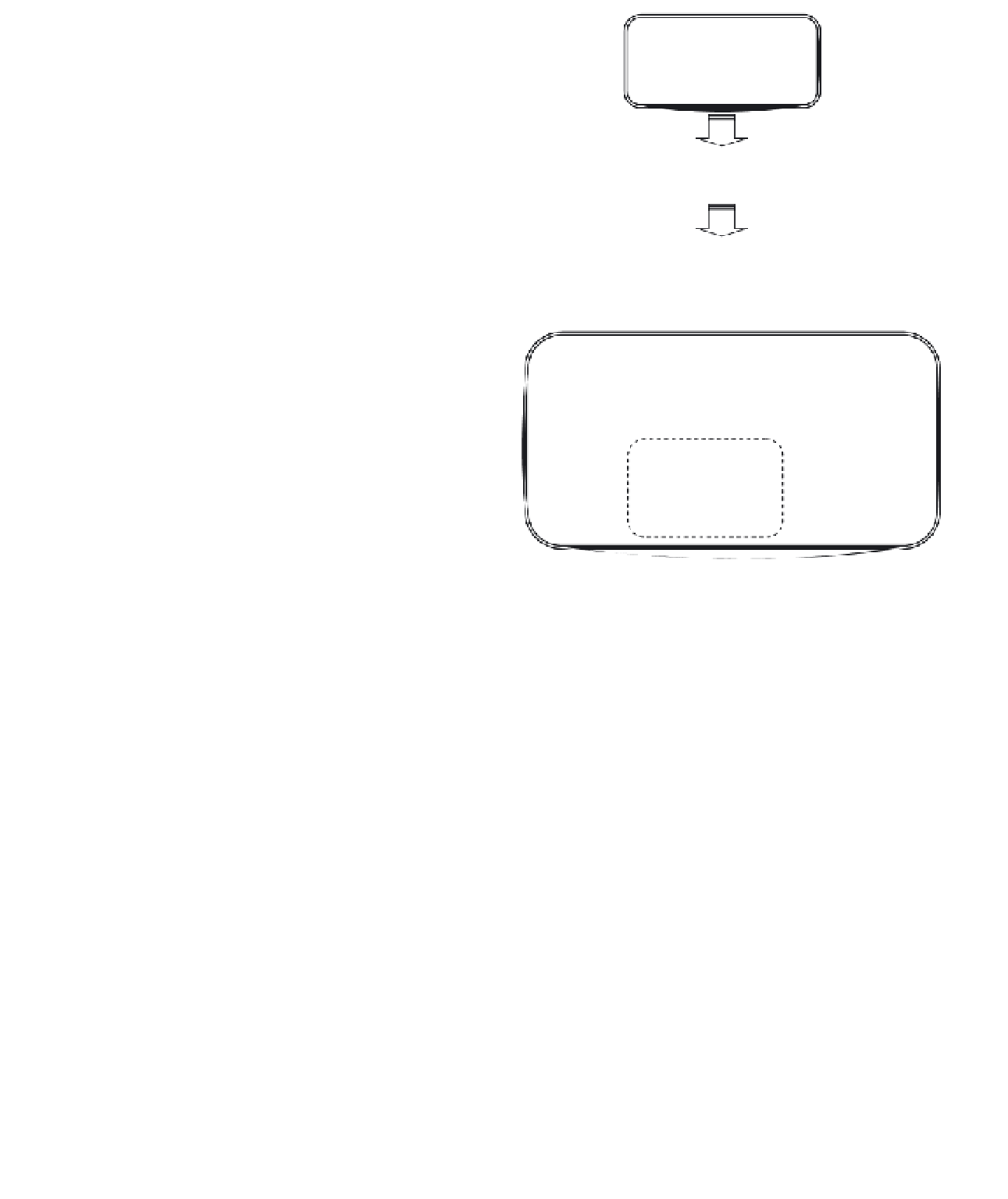

A typical olive oil processing outline is shown in Figure

26.5. A detailed description of various steps involved in

olive oil processing is given in the following paragraphs.

Liquid-liquid separation

Preparation operations

Olive harvesting

This is one of the most important stages in the process of

obtaining virgin olive oil since it largely determines the

cost of virgin olive oil and directly contributes to its qual-

ity. As much as possible, the optimal degree of ripeness in

the olives should be determined, as this affects not only the

fruit's maximum oil content but also other compounds that

are responsible for its sensory properties. The ideal method

involves picking the fruit directly from the tree in order to

avoid damaging the fruit and the tree (as for table olives;

see section “Harvest, Storage, and Shipping Practices”).

However, this is not always possible due to cultivation tech-

niques, the tree canopy, terrain features, and price, which

may require mechanical systems to facilitate the task, such

as vibrating machinery. To date, Spain has developed new

varieties of olives where the size of the tree has been se-

lected for an intensive crop (2000 trees per hectare) to use

harvesting machines designed for “hedgerow” cultivation

(Rallo et al., 2008).

Storage

Figure 26.5.

Flow diagram of olive oil processing.

In any case, the objective should be to avoid harvesting

fruit that has fallen to the ground at all costs as the fall usu-

ally damages the fruit, which negatively affects the quality

of the olive oil.

Shipping and postharvest losses

Care should be taken so that fruit is not compressed during

transportation. The optimal system for accomplishing this

is the use of plastic boxes with holes for providing the fruit

with ventilation and to help disperse the heat produced (Di

Giovacchino, 2003). Ideally, the fruit should be processed

on reaching the mill, to avoid undesirable reactions. This

is not always possible, however. In this situation, the fruit

undergoes a series of transformations that lead to a loss

of quality that includes fermentation (due to increased

Search WWH ::

Custom Search