Agriculture Reference

In-Depth Information

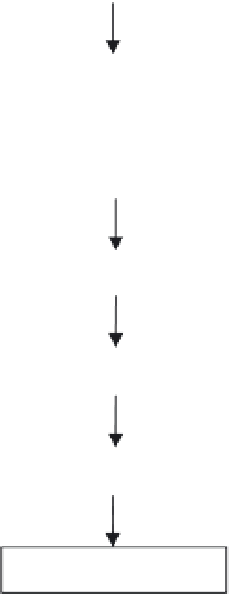

Dried peels

Supernatant:

Pigments, etc.

0.03 N NaCl

Washing

0.04 N NaCl

Hydrolysis

Hot water

Residue

Pectin extraction

Liquid extract

Permeate:

Flavonoids, carotenoids, etc.

Microfiltration

Retentate

Permeate:

Flavonoids, carotenoids, etc.

Water

Diafiltration

Retentate

Supernatant

Precipitation

95% ethanol

Precipitated gel

Ethanol washing

95% ethanol

Supernatant

Pectin gel

Freez drying

Water, ethanol

Pectin product

Figure 22.4.

Flowchart of pectin extraction from mandarin peels (source: Adapted from Cho et al., 2003).

content of pectin increased from 72.2% to 75.6%. The di-

afiltration process was also effective to remove flavonoids,

polyphenols, and carotenoids, which are impurities in

pectin products. Cho et al. (2003) recommended that the

cross-flow microfiltration system could be efficiently used

for concentration and purification of pectin.

Some other products are also available in market that can

be considered as citrus industry by-products like citrus peel

powder, seed oil, vinegar, and so on. The citrus seed oil is

of considerable importance as it falls under the category

of unconventional edible oil sources. However, the seed

oil production is limited in some species of easy peelers

like clementine and satsuma as they are seedless in na-

ture (although there may be some variations). Chemically,

orange oil contains about 90% d-limonene, with proven

health claims. Moreover, it is the ingredient of choice for

replacing the synthetic cleansing agents. Its smell is con-

sidered more pleasant than those of other cleaning agents

(Feger et al., 2003).

Innovative processing technologies

A number of innovative processing technologies have been

developed and are being used for fruit processing, for ex-

ample, high-pressure processing (Linton et al., 1999; Hsu

et al., 2008; Polydera et al., 2005), pulsed electric field

(Ayhan et al., 2002; Barbosa-Canovas et al., 1999; Min

and Zhang, 2003; Rivas et al., 2007), membrane filtration

Search WWH ::

Custom Search