Agriculture Reference

In-Depth Information

in 2001. HACCP, which is an acronym for hazard analy-

sis/critical control points, is a food safety system intended

to minimize the risk of food-borne illness due to a particular

product. HACCP is implemented by a food safety team that

evaluates the potential hazards of a product and its process

and their severity and then identifies the critical steps in the

process that provide a control for those hazards. In orange

juice processing and packaging, there are two critical con-

trol points (CCPs) that must be addressed, although some

processors/packagers identify and control additional CCPs.

A necessary CCP for most orange juice processors is

the control of potentially hazardous metal fragments and

inclusions in the juice. The potential for metal breakage

and fragmentation during the processing steps of extrac-

tion and finishing is relatively high due to the nature and

operation of the equipment. Most processors use a series of

screens, one of which is designated as a CCP, to prevent the

inclusion of metal pieces. Metal fragments in the finished

(packaged) product may also be controlled through the use

of metal detectors. Another CCP in the orange juice process

is a pasteurization treatment sufficient to reduce pertinent

pathogens (in this case,

Salmonella

spp.) by a factor of 5

logarithmic units or 5-log reduction (99.999%). Most pro-

cessors/packages accomplish this step through thermal pro-

cesses, namely, shell-and-tube heat exchangers that quickly

pasteurize, then chill, the juice. For both CCPs, monitoring

records as well as corrective action records must be kept.

The juice HACCP regulation is further discussed on the

FDA's Juice Safety website (FDA, 1997).

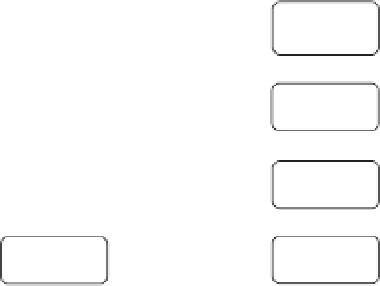

ORANGE BY-PRODUCTS

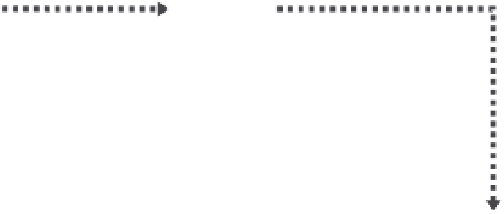

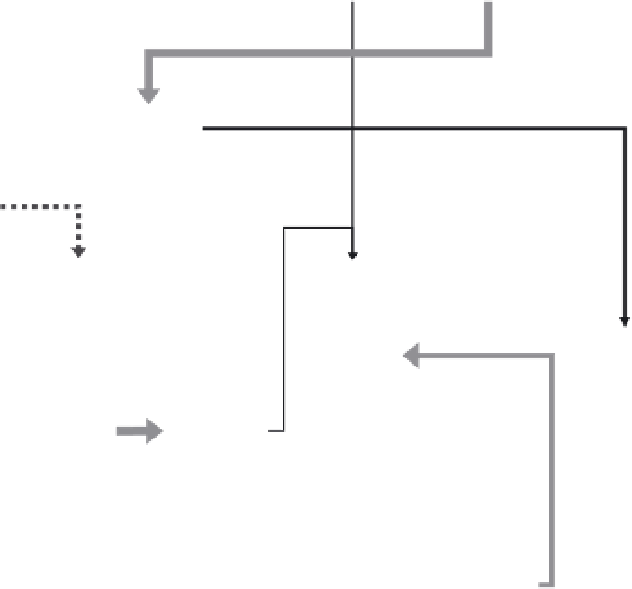

Several by-products are obtained from orange processing.

A mass balance of the major by-products is shown in

Fig. 21.7. A major discussion of citrus by-products has

been published (Braddock, 1999a).

Storage in

bins

Oil

emulsion

Receiving

Unloading

Grading

Washing

Grading

Sizing

Fruit

SSC/TA

analysis

560 kg

Pulpy juice

Oil emulsion

Extraction

Peel and rag

440 kg

60 kg

Pulp

Defect

removal

Finishing

(c)

(d)

(e)

500 kg

Juice

Hard finishing

Finishing

Size

Molasses (50ºBrix)

(a)

(b)

51.5 kg

Centrifugation

stage 1

Centrifugation

Pasteurization

Pasteurization

Hydrolysis

Pasteurization

Water

Press liquor

Deaeration/

deo iling

Centrifugation

(polishing)

Pulp Wash

Evaporation

Pressing

92 kg

286 kg

Wax

Pasteurization

Pasteurization

Cooling

Drying

Winterizatio

Finishing

Frozen

storage

Aseptic

storage

Frozen

storage

Frozen

storage

Condensation

Evaporation

Pelletizing

Evaporation

not from

concentrate

(12ºBrix)

frozen

concentrate

Aqueous

aroma

Pulp

(500-900 g/l)

Pulp wash

Dry cattle

feed

d-limonene

(100%)

Essential oil

(100%)

(65ºBrix)

(65ºBrix)

500 kg

92.3 kg

0.6 kg

49 kg

9 kg

98 kg

1.1 kg

5 kg

Figure 21.7.

Schematic of orange juice and orange by-product processing. Mass balance values are

approximate as they vary depending on processing conditions.

Search WWH ::

Custom Search