Agriculture Reference

In-Depth Information

Technologies Corporation (JBT), formerly known as FMC

FoodTech, whose extractors produce approximately 75%

of the world's citrus juices, and Brown International Cor-

poration. Detailed information on these extractors is given

on the websites of the two companies (BIC, 2011; JBT,

2011).

Briefly, in Brown extractors, fruit is loaded into a

carousel made of a set of hemispherical cups that hold the

fruit while a blade cuts it into two pieces. The cups holding

one-half of each orange are spread apart and pressed against

a spinning reamer. Pressure and gap between reamer and

cup are among the critical adjustment parameters in Brown

extractors. Each extractor can handle 4-14 ton fruit/hour.

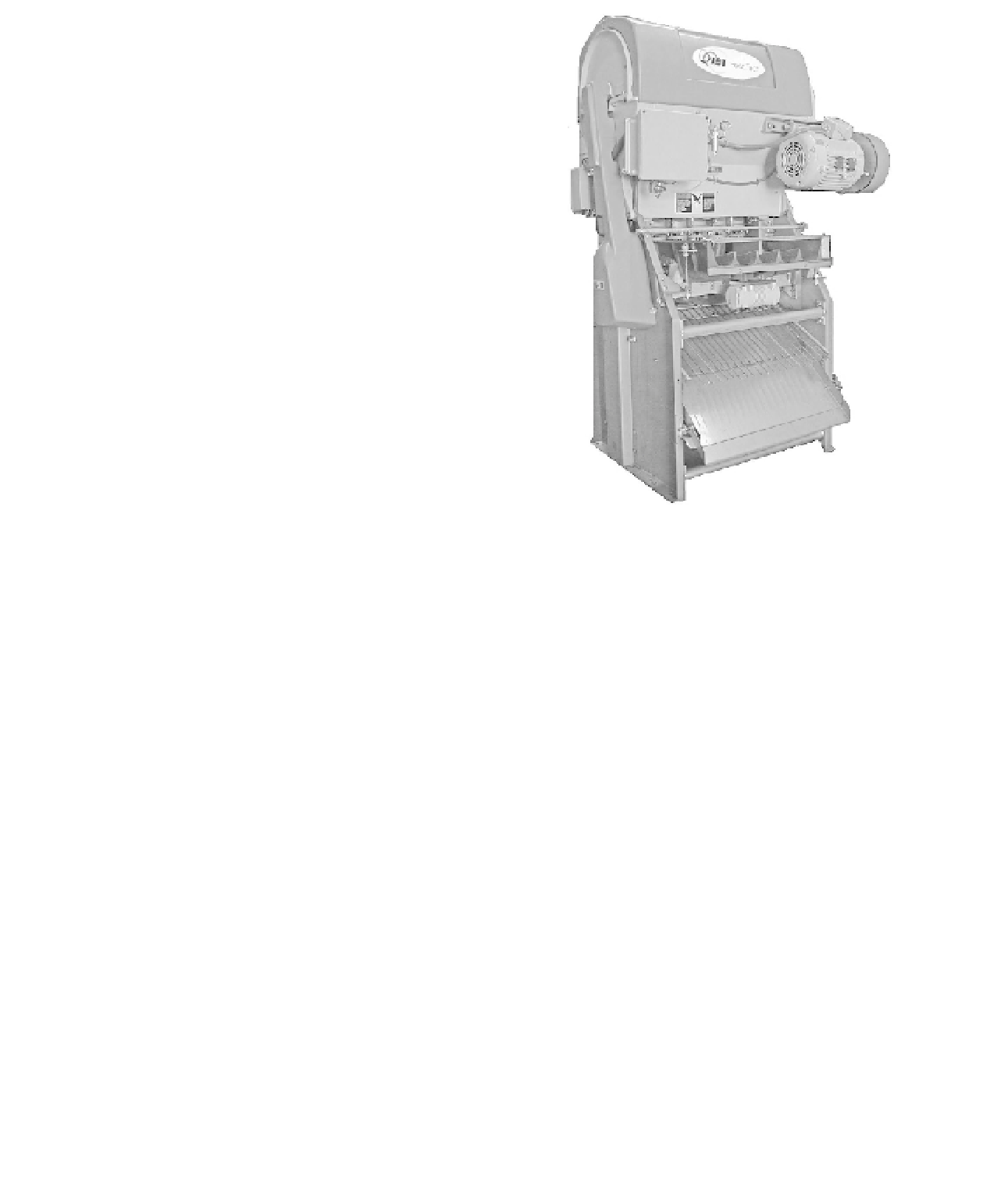

JBT extractors are typically configured with either three,

five, or eight cups, with five cups being the most common.

Cups are made of a hard cast stainless steel alloy and are

formed by an array of rigid “fingers” that join at the bottom

of the cup with an orifice at the center. Fruit is fed onto

the lower cups and then pushed downwards with the upper

cup. As the fruit is being pushed, the peel detaches from the

juice segments. The peel falls off and out of the extractor,

and the juice with the fruit core and segment membranes

is then pushed inside the strainer tube. The juice flows

through the strainer tube holes acting as a prefinisher. The

fruit core, segment membrane, and peel particles are ejected

out the bottom of the tube. Synchronization of all moving

parts is critical to effective and efficient operation of JBT

extractors. Also, the size of the holes in the prefinisher is

critical to the quality of the juice and the pulp recovered

from this extractor. JBT extractors have a capacity of up to

600 fruits per minute or about 10 ton fruit/hour. Fig. 21.5

shows a Model 391 extractor from JBT.

Extracted juice flows to finishers that decrease pulp con-

tent to about 20% to 25% of floating and sinking pulp.

There are two types of finishers: screw and paddle. In both

cases, fruit fed into the finisher is conveyed and pushed by

the screw or the paddle against a mesh. The juice flows

through the mesh while the pulp is retained and flows out at

the end of the finisher. Mesh size and gap between the screw

(or paddle) and the sieving screen determine the extent of

separation. Juice quality is also affected. Tight finishing

results in drier pulp and increase juice yield. However, ex-

cessively tight finishing extrudes pulp particles through the

screen and deteriorates the quality of the juice as bitter com-

pounds present in pulp and other residues are incorporated

into the juice. Some processors use a cyclone between ex-

tractors and finishers to remove defects such as embryonic

seeds. Defect removal is particularly important when pulp

is intended to be sold as a by-product. Screw finishers from

JBT are controlled based on the pressure applied between

Figure 21.5.

Commercial orange juice

extractor—JBT, Model 391.

the product and narrow portion of the tapered screw as the

gap between the screw and the screen is adjusted. Brown

systems are controlled based on a temperature difference

between juice entering the finisher and the pulp exiting it.

Similarly, the gap between screw and screen is adjusted

to produce the desired temperature. In each case, finishing

pressure or temperature difference is correlated to the water

content of the pulp recovered from the finisher.

Pasteurization

Thermal

Finished orange juice is pasteurized not only to destroy

pathogenic and spoilage micro-organisms but also to in-

activate pectinesterase (PE), an enzyme that causes juice

cloud precipitation. Because PE is more resistant to heat

than the pathogens of interest, the time-temperature pro-

file for pasteurization, typically at 85

◦

-90

◦

C for 10-15 sec,

is based on PE inactivation. Pulpy orange juice is pas-

teurized in tubular pasteurizers. Plate heat exchangers are

occasionally used when pulp content is low because pulp

fouls conventional plate heat exchangers.

Search WWH ::

Custom Search