Agriculture Reference

In-Depth Information

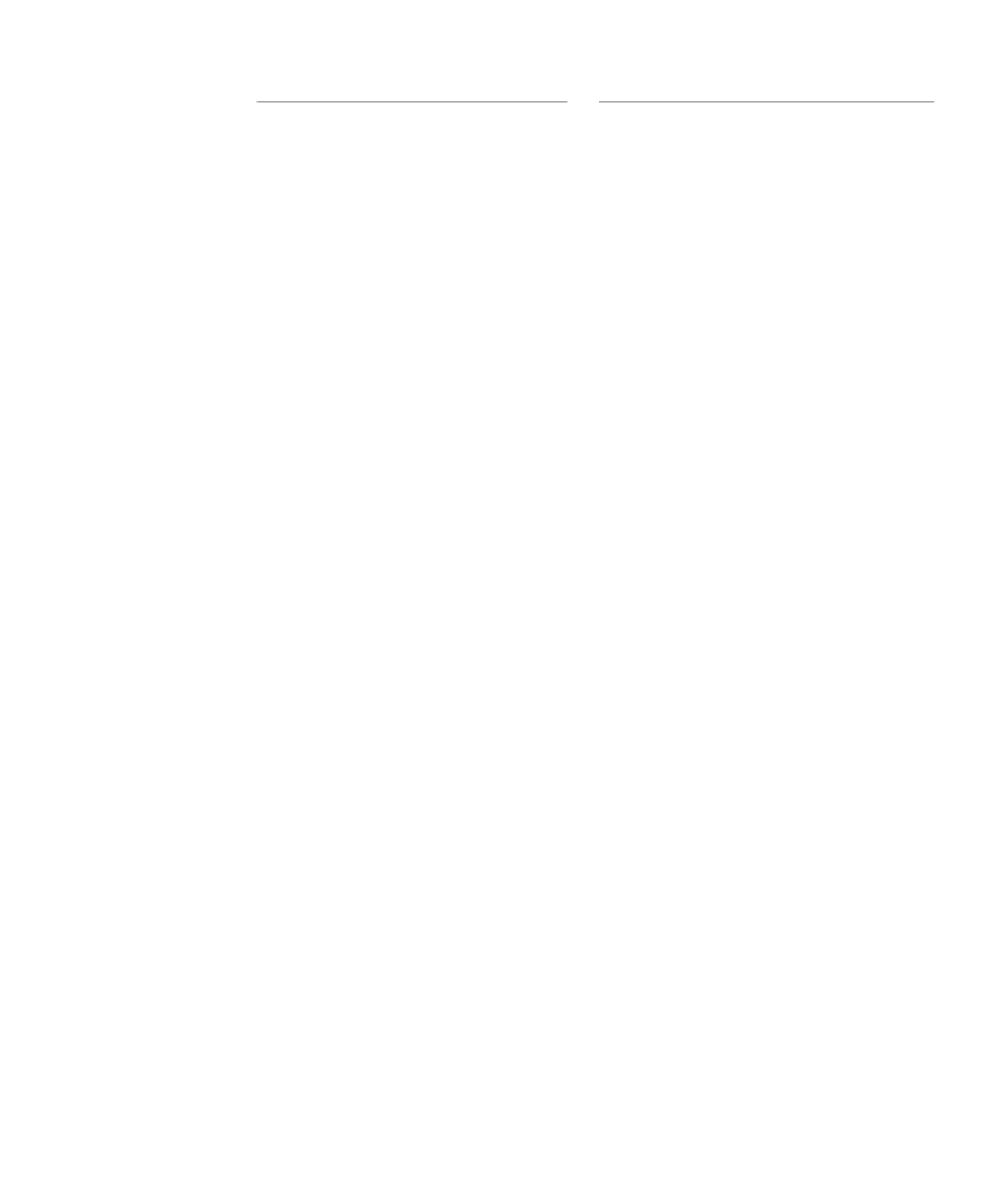

Table 21.4.

Quality standards for canned not from concentrate (NFC) and canned concentrated orange

juice.

Canned NFC

Concentrated

Characteristic

USA

Europe

USA

Europe

10.5

1,2

10

5

11.2

5

Soluble solid content

>

>

11.8 after 3:1 water:concentrate

dilution ratio

1

(SSC, as Brix)

41.8

2

>

1.6

3

Titratable acidity

>

—

Brix/acid

4

9

2,3

>

11.5-20.0

0.05

3

0.03

5

0.035

2

0.03

5

Oil in juice

<

<

<

<

Equal or better than USDA OJ 5

2

Color

Equal or better than

USDA OJ 6

2

Not allowed

1

Pulp wash

Not allowed

Allowed

Allowed

Up to 10%

1

Up to 10% prior to concentration

1

Tangerin/ambersweet

(

Citrus reticulata

/

Citrus reticulata

hybrids) addition

Allowed but must be labeled

1

Sugar addition

Allowed but must

be labeled

1

Up to 15 g/liter

must be declared

in ingredient list

1

21 CFR 146.140 and 21 CFR 146.141;

2

USDA Standards for grades of orange juice;

3

Ch. 601 Citrus Code;

4

Brix-acid

ratio ranges given by the USDA depend on SSC;

5

Association of the Industry of Juices and Nectars (AIJN)

recommendation.

contracts are 3-5 years and are negotiated directly with the

growers, and others are negotiated through intermediaries

also called “bird dogs.” Prices are determined in four main

ways: (1) cash market, where the price is agreed upon and

fixed for the duration of the contract; (2) reference pricing,

where the price is based on the market price of juice or

comparative products or markets; (3) toll process pricing,

where the owner of the fruit has the processor process the

juice into not from concentrate (NFC) or concentrate for

a fee rather than selling the fruit to the processor; and

(4) participation program pricing, where the price paid for

the fruit is a function of the average selling price of the

juice over an agreed period of time (Morris, 2010a).

After unloading, trash (e.g., leaves, twigs, sand, and other

foreign material) is mechanically removed. Fruit is pre-

sorted using a combination of manual and mechanical sep-

aration to remove very small or split fruit. Only 2% decay

and a maximum of 10% of unwholesome fruit are permit-

ted. Presorted fruit is then stored in bins, with a statistically

representative sample analyzed for quality parameters. Pro-

cessors decide what bin to unload for processing based on

fruit quality, juice analyses, and size. Fruit is then washed

with water and sanitized by spraying water and sanitizer

on the fruit through nozzle manifolds as it is conveyed off

the storage bins. When fruit feeding rate is greater than the

rate of extraction, fruit is returned on a conveyor parallel

to the feed conveyor, and bin unloading is slowed down or

stopped as needed, thus controlling the rate of bin unload-

ing. Direct unloading, that is, bypassing storage bins, is

also done in Florida and Brazil to improve juice quality and

reduce costs by reducing fruit damage caused by handling

during bin storage. Fruit is sized as it enters the extraction

line by conveying it along semiparallel rollers from a grad-

ually increasing gap. Small fruit falls through the small gap

at the beginning and large fruit falls last. Sizing is critical

to optimize juice yield and quality because juice extractors

are adjusted according to the fruit size they receive.

Juice extraction and finishing

About 80% of all oranges processed in the United States

are 7.3

1.25 cm in diameter. Some juice extractors, in

particular those that handle small fruit, need to be adjusted

regularly due to seasonal and/or varietal differences. There

are two main juice extractor manufacturers, John Bean

±

Search WWH ::

Custom Search