Agriculture Reference

In-Depth Information

The harvested fruits are subjected to fungicide treatment

before degreening, waxing, or storing, the effectiveness

of which depends on prompt treatment of the fruit. The

maximum time between harvest and treatment varies with

temperature but should not exceed 24 hours (Hardy, 2004).

Two methods may be used for fungicide treatment of fruit-

bulk dipping: shower or spray application and fungicide

stripping. Bulk dipping is the complete immersion of bulk

bins of citrus in a fungicide solution for at least 30 sec. It is

a convenient method of fruit treatment within 24 hours

of harvest when the fruits are not packed or processed

immediately. Fruits are treated for 30 sec by using shower

or spray application over revolving brushes or rollers and

are thoroughly coated with the fungicide as the fruits move

through the packing line. Accumulated dirt and organic

matter bind some fungicides and reduce their effectiveness.

The type of fungicide application equipment used and the

water quality can influence the rate of loss of the fungicide,

hence the concentration of fungicide in the dip tank and

inline equipment are monitored at regular intervals. Correct

concentration of fungicide in the water can be achieved by

changing fungicide tanks regularly or by topping off with

more fungicide (Hardy, 2004).

Washing the fruit removes soil and dirt particles, disease

spores and field spray residues. Sometimes, high-pressure

water sprays are used to clean pests and diseases from fruit

and this can disturb the natural wax layer of the fruit. It is

important that the water used is clean and free of disease

spores to avoid contamination of the fruit. Water can be

treated with sanitizer (e.g., chlorine compounds) to kill

the free floating spores. The pH and temperature of the

water can affect the activity of sanitizers and fungicides

and therefore are monitored regularly (FAO, 1989; Hardy,

2004).

Waxing is used to improve the appearance of fruit, protect

the fruit surface, slow down the development of some rind

disorders, and, most importantly, reduce water loss from

the fruit (Morton, 1987a, 1987b; Goodrich, 2003; Hardy,

2004). Waxes used on fruit are edible and include Carnauba

(a natural wax extracted from palm leaves), shellac-based

waxes, polyethylene-based waxes, and resin-based waxes.

Wax is applied evenly at low pressure to the fruit surface

without diluting with water. Wax is sprayed or dipped onto

damp fruit while they are being rotated on a bed of revolving

brushes that help to spread the wax evenly over the fruit

surface. Fruits are then dried by running high velocity air

across the fruit for 2.5-3 min. Cool or warm air is used,

depending on conditions.

Fruits are sorted on the packing line to remove blem-

ished or damaged fruits and graded according to market

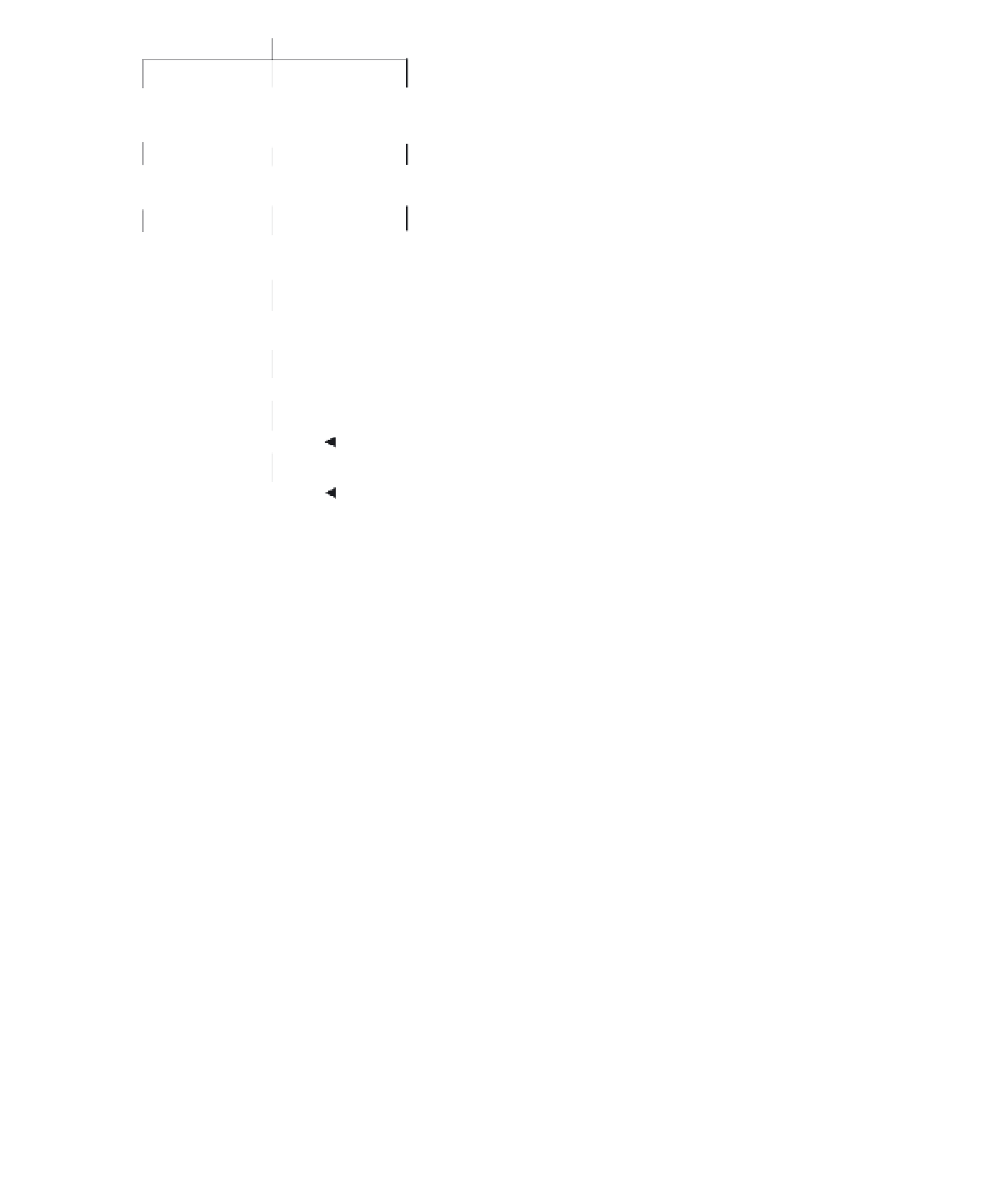

Harvest Fruit

If degreening

treatment

needed

If packing within

24 hours or long-

term storage

If storing fruit for

short-term

(>24 hours)

Bulk-dip in

fungicide

Sort out fruit to be

discarded

Bulk-dip in

fungicide

Degreen

Store

Wash and

clean fruit

In line Fungicide

treatment

Wax and dry

Long-term

storage

Grade and Pack

Market

Repack

Figure 20.3.

Simple postharvest handling sequence

(source: Hardy, 2004).

the major unit operations in packing fresh lemons and limes

are the same as for other citrus fruit. Simple postharvest

handling sequence is detailed in Fig. 20.3. Lemons and

limes picked while still green will generally have a longer

postharvest shelf life than the fully yellow lemons that need

to be handled gently and marketed more rapidly (Goodrich,

2003). Harvested fruit may undergo three different treat-

ments, depending on the objective. The fruit may be de-

greened, packed within 24 hours, or packed for long-term

storage or stored for short periods (

24 hours). Any fruit

that will not be packed is removed from the line prior to

fungicide application and waxing. Mature lemons that may

lack full color development can be degreened by exposing

the lemons to 1-10 ppm ethylene gas (a natural product of

fruit ripening) for 1-3 days at 20

◦

-25

◦

C prior to waxing

(Goodrich, 2003). This gas causes the breakdown of the

green pigment in the fruit rind and the fruit develops a far

more acceptable yellow color. Ethylene does not ripen fruit

and does not affect the sugar, acid and flavor of the fruit.

The greener the fruit, the longer it takes to degreen. De-

greening can also be achieved by spraying with gibberelic

acid.

<

Search WWH ::

Custom Search