Agriculture Reference

In-Depth Information

the country to which product will be exported. General

food laws, certificate of conformity, maximum residue lim-

its, and phytosanitary regulations and plant protection are

important. Moreover, certifications such as EUREPGAP,

HACCP, ISO 9001, ISO 9002, and ISO 14001 are impor-

tant requirements for exports.

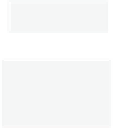

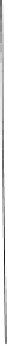

FRESH-CUT PROCESSING

Fresh-cut fruit and vegetable products have become in-

creasingly popular owing to their convenience to the con-

sumer and the human health benefits associated with eating

these foods. The market for ready-to-eat papaya is very

small but growing (Anon, 2009). Fresh-cut papaya fruit

undergo rapid tissue deterioration during storage showing

translucency, darker flesh, and dehydrated surface (Paull

and Chen, 1997). Figure 16.3 shows a general diagram of

the basic operations performed to obtain fresh-cut papaya.

During processing hurdles technologies such as sanitizing,

addition of antioxidant or texturizing compounds, coatings,

radiation, mild heat treatments, modified atmospheres, re-

frigeration, and so on, are applied to prolong the shelf life

and to assure a microbiologically safe product, while re-

taining its sensorial and nutritional characteristics.

Artificial ripening

Ethylene-treated papayas ripen faster and more uniformly

in terms of skin degreening, softening, and flesh color (An

and Paull, 1990). Since papaya ripens from the inside out-

ward, ethylene treatment is used to accelerate the rate of

ripening of the mesocarp tissue nearer the skin that has

not started to soften. Exposure to 100 ppm ethylene at

20

◦

-25

◦

C and 90-95% relative humidity for 24-48 hours

resulted in faster and more uniform ripening of papayas

picked at color break to 1/4 yellow stage (O'Hare, 1993) In

warmer months, fruit is allowed to ripen naturally. Ideally,

fruit should reach the market with between 1/2 and 2/4 yel-

low in summer and between 3/4 to full color in the winter

months (Papaya Australia, 2007).

Microbiological quality

O'Connor-Shaw et al. (1994) and Hernandez et al.

(2006) observed that the total microbial content, aerobic

mesophiles, and fungi and yeasts were relatively high when

Harvesting

Sorting

Postharvest

treatment

Ripening

Washing

Peeling

Deseeding

Cutting

FROZEN

DEHYDRATED

CANNED

FRESH

FRESH-CUT

PUREÉ

CONCENTRATE

JUICE

Antioxidant

treatment

Antioxidant

treatment

Filling in

cans

Antioxidant

treatment

Retail

boxing

Sanitation

Antioxidant

treatment

Antioxidant

treatment

Textural/

antioxidant

treatments

Hot air/

Freeze-drying/

Osmotic

Syrup

addition

Freezing

processing

Blending/

Extraction

Blending/

Extraction

Blending/

Extraction

Refining

Can closing

Pasteurization

Refining

Package film

MAP

Thermal

processing

Evaporation

Pasteurization

Storage at

−

Storage at

25°C

Storage at

10°C

Storage at

5°C

Storage at

25°C

Storage at

25°C

Storage at

25°C

Storage at

25°C

20°C

Figure 16.3.

Flow diagram for processing different papaya products.

Search WWH ::

Custom Search