Agriculture Reference

In-Depth Information

70

(d)

(c)

60

(m)

Drying unit (b)

50

40

0.96 m

(y)

30

(x)

20

(k)

10

0.75 m

0

(e)

2.02 m

A

B

C

D

E

F

Solar collector (a)

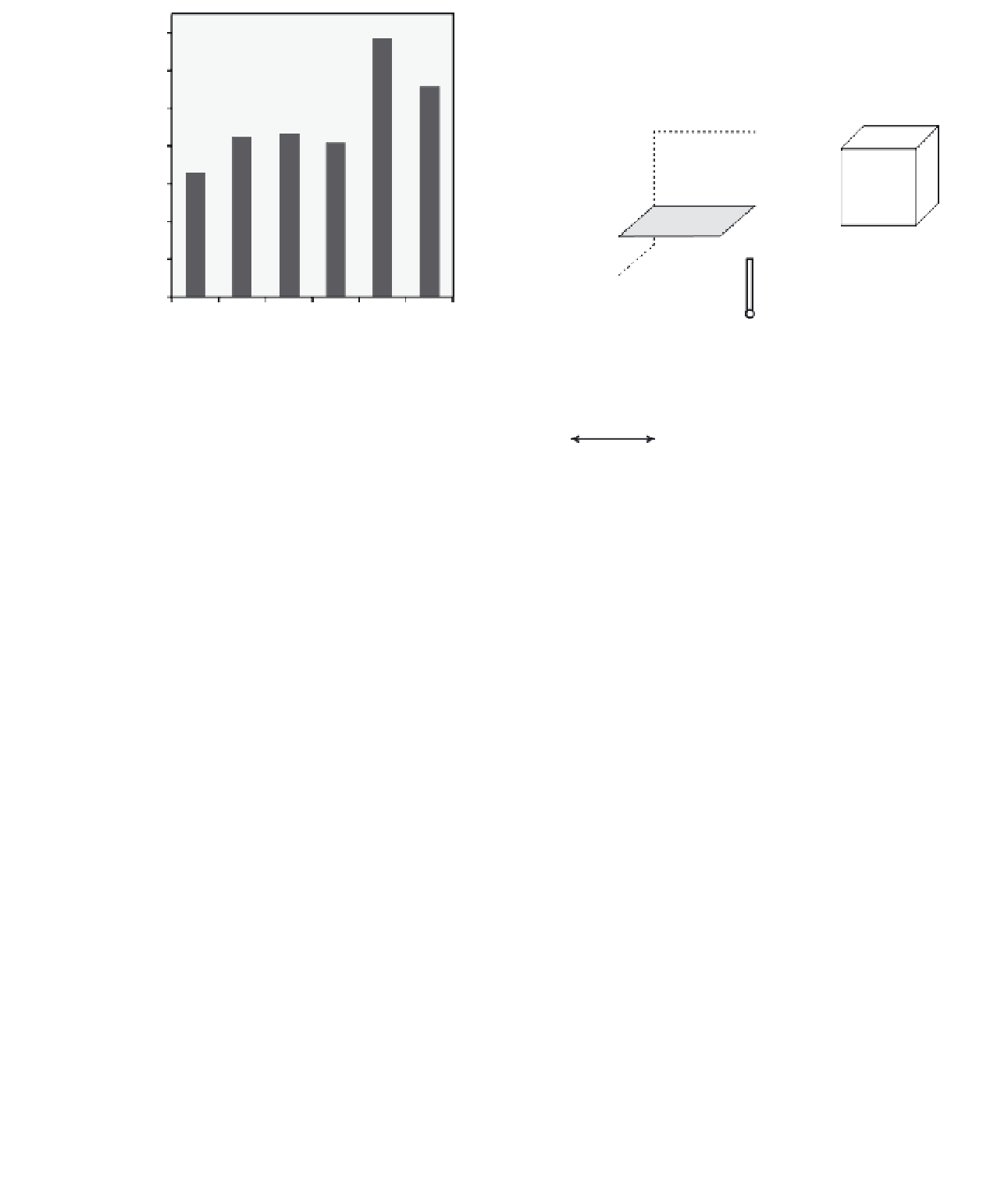

Figure 15.7.

Effect of different drying methods on

total carotenoid content of mango. Mango pieces

were (A) dried under hot air at 60

◦

C for 20 hours,

(B) soaked in 1% sodium hydrogen sulfite solution

for 30 min prior to treatment A, (C) soaked in 1%

ascorbic acid solution for 30 min prior to treatment

A, (D) freeze-dried (-53

◦

C, 0.06 torr) for 32 hours, (E)

soaked in 1% sodium hydrogen sulfite solution for

30 min prior to treatment D, and (F) soaked in 1%

ascorbic acid solution for 30 min prior to treatment

D (source: Adapted from Chen et al., 2007).

0.85 m

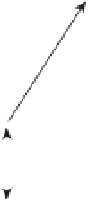

Figure 15.8.

Prototype of indirect solar dryer.

Labeled parts are (A) solar collector; (B) drying unit;

(C) chimney; (D) air extractor; (E) air entrance; (K)

drying unit bottom side; (X) drying unit small side;

(Y) drying unit large side; and (M) air recycling pipe

(source: Dissa et al., 2009).

before hot-air drying, freeze-drying (40.73

μ

g/g), and hot-

air drying (32.74

μ

g/g) without soaking.

In the developing countries, mango slices are also dried

under sun or using solar dryers, the main reasons for the

use of these indigenous methods are the high energy re-

quirements and equipment costs for commercial equip-

ment. Dissa et al. (2009) developed a prototype indirect

solar dryer (Fig. 15.8). Exposed to solar radiation, the solar

energy collector panel converts into heat a portion of radiant

energy received on its surface. The air crossing the porous

matrix of its absorber then receives a portion of this energy

by convective heat exchange; the resulting heated air circu-

lates in the unit for drying mango slices laid out in single

layer in mesh trays (Dissa et al., 2009). Mango slices of

8 mm thickness were successfully dried in 3 days. The final

water contents corresponding to 0.6

an air convection oven. Vacuum dryers can also be used

(2-4 mmHg, 60

◦

-66

◦

C) to achieve a final moisture of 2%

(Narain et al., 1998). The volatile profile of mango may

be affected by process conditions in osmotic treatments.

In general, the use of highly concentrated osmotic solu-

tions and the high level of osmodehydration induces loss

of volatiles. Conversely, more diluted solutions and shorter

treatment times (lower osmodehydration level) can give rise

to the enhancement of volatile production, which could be

positive for the fruit aroma perception (Torres et al., 2007).

Welti et al. (1995) reported a 50-75% reduction in drying

time requirement of osmotically pretreated mango slices as

compared to fresh mango slices dried conventionally.

Mango chips and flakes

Development of high-quality mango chips using vacuum

frying was investigated by Nunes and Moreira (2009).

'Tommy Atkins' mango slices were pretreated with dif-

ferent maltodextrin concentrations (40%, 50%, and 65%,

w/v), osmotic dehydration times (45, 60, and 70 min),

and solution temperatures (22

◦

and 40

◦

C). Pretreated slices

were vacuum fried at 120

◦

, 130

◦

, and 138

◦

C, and product

0.02 water activities

were in accordance with those required for optimum shelf

life (Dissa et al., 2009).

Osmotic dehydration is another method being used in-

creasingly to produce dehydrated mango products (Giraldo

et al., 2003). Osmotic dehydration involves dipping mango

slices in 70

◦

Brix sugar syrup, draining, dipping in sulfite

solution followed by a second draining, then drying in

±

Search WWH ::

Custom Search