Agriculture Reference

In-Depth Information

Fruits

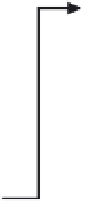

Puree/Juice extraction

Partial enzymatic

liquefaction

Light enzymatic

maceration

Crossflow microfiltration

Pasteurization

Thermal

concentration

Clarified

juice

Permeate

Retentate

Pulpy Juice concentrate

Thermal

concentration

Membrane

concentration

Blending

Top-grade concentrate

with variable pulp content

Clarified juice

concentrate

Top-grade clarified

juice concentrate

Figure 15.6.

Proposed flowchart for producing clarified juice and juice concentrate from pulpy juices at an

industrial scale (source: Vaillant et al., 2001).

furfural, cis-3-hexen-1-ol and hexanol by 23.4%, 79.1%,

93.8%, and 128.6%, respectively. Moreover, 2-hexenal

(0.28%) and octadecanal (0.24%) were only found in UHP-

treated mango juice. Sensory analysis revealed that UHP

processing increased the green flavor and preserved the

characteristic aroma of mango fruits.

In comparison to pulp, the chemical composition of

canned mango juice is characterized by a lower content

of ascorbic acid, free amino nitrogen, reducing sugars, and

carotenoids (Table 15.2), while the pulp is characterized by

lower TSS, higher pH, lower total sugars, and lighter color

(Ragab and El-Nemr, 1990).

Changes in quality attributes of sweetened mango juices

prepared from 'Julie' and 'Ogbomoso' varieties were in-

vestigated by Falade et al. (2004) during storage at 25

◦

C

for 12 weeks. The titratable acidity, pH, total solids, ash,

soluble solids, and ascorbic acid contents decreased during

storage. After 12 weeks of storage, percentage losses of

ascorbic acid by sweetened 'Julie' and 'Ogbomoso' mango

juices were 16.25% and 16.67%, respectively. Browning in-

dex, chroma, and

b

∗

values increased during storage. Color

changes in sweetened mango juices were mainly due to

changes in

b

∗

value and chroma.

Mango squash and aseptically packaged mango

beverages

Juicy varieties of mangoes are preferred for making mango

squash “drink,” which is another category of beverage made

from mango pulp. Mango nectar and squash are similar

in composition, except for the presence of a preserva-

tive: 0.1% sodium benzoate or 350 ppm SO

2

in squash

(Occena-Po, 2006). Mango squash formulation consists of

blending 68

◦

Brix syrup with mango puree, citric acid, and

potassium metabisulfite (Narain et al., 1998). The contents

are heated to about 90

◦

C and hot-filled into presterilized

glass bottles. Bottles are closed with screw-type caps or

cork stoppers; if cork stoppers are used, the bottles are in-

verted in hot-wax to put a coating on the cork and bottle

neck to make the closure air tight. Mango squash is diluted

approximately three times with water before serving in the

chilled form.

Search WWH ::

Custom Search