Agriculture Reference

In-Depth Information

Harvesting

Mature mangoes

Ripe mangoes

Washing

Washing

Slicing

Peeling

Pulping

Peeling

Slicing

Pulping

Fresh-cut

Slices

Canned

Slices

Dehydrated

Slices

Canned

Pulp

Pickle

in Oil

Mango

Powder

Mango

Chutney

Juice

Heating

(45-50°C)

°Brix (16-18),

pH (3.8-4.0)

Adjustment

Salting

Antibrowning

treatment

Sanitizing

Sorting

Sanitizing

Sieving

Antibrowning

treatment

Antibrowning

treatment

Exposure

to sun

Sugar/Spices

Addition

(chilies, salt.

black pepper)

Filling

Enzyme

treatment

Solar drying

Sieving

Syruping

(40% sugar

Drain

excessive

moisture

Cabinet

drying

Adding and

mixing oil

Grinding

+

0.3% citric acid)

Filling and

can closure

Sieving

0.5% Citric acid

addition

°Brix (~15),

acidity (0.3%)

adjustment

Sieving

Packaging In

polyethylene

film

Spices addition

(Turmeric,

fenugreek seed,

chilies, ginger,

black pepper)

Can closure

Thermal

processing

Packaging

(Regular or

modified

atmosphere)

Packaging in

polyethylene

film

Cooling and

hot-filling (85°C)

Thermal

processing

Filling

Cooling

Labeling

Thermal

processing

Cooling

Labeling

Labeling

labeling

Cooling

Curing in sun

Storage (25°C)

Cooling

labeling

Labeling

Storage (5°C)

Storage (25°C)

Storage (25°C)

Labeling

Labeling

Storage (25°C)

Storage (25°C)

Storage (25°C)

Storage (25°C)

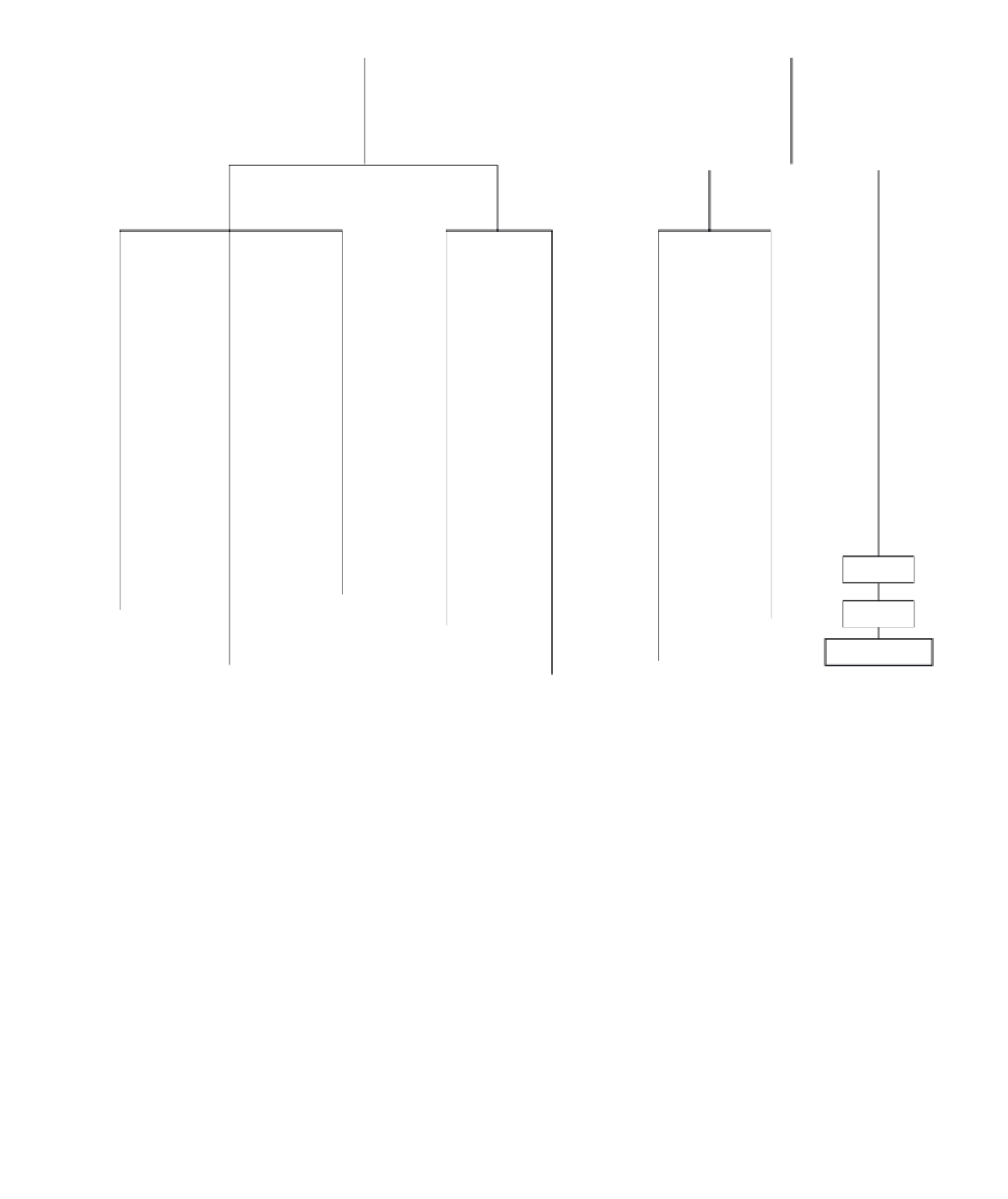

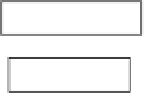

Figure 15.5.

Typical processing outline for production of different mango products.

MANGO PROCESSING AND PRODUCTS

Being a prime table fruit, mango with its delicious pulp

is perfectly suited for preparing a number of nutritious

processed products, including juices, nectars, drinks, jams,

squash, leather, and pickles (Akhtar et al., 2009). Owing

to its higher moisture contents and relatively shorter shelf

life, the postharvest losses of mango are excessive in In-

dia and Pakistan, where only about 5% mangoes are pro-

cessed and mango pulp is the main export product both

in terms of volume and value ( Hanemann, 2006; Babitha,

2009). Currently, chemically preserved, canned, dried, and

frozen forms of mango pulp and jams, jellies, canned slices,

dehydrated pulp (mango leather), frozen chunks and slices,

traditional pickles, and chutneys are commonly processed

from mangoes (Akhtar et al., 2010a).

Bulk of immature mangoes often blown down by spring

winds are best utilized to produce mango powder (

am-

choor

). Other mango products of significance include

sauces and jelly made of half-ripe or green mangoes, peeled

and sliced as filling for pie. Many types of chutneys are

manufactured by using green mangoes with added sugar,

salt, and various spices (Morton, 1987).

Most of the preparation steps, for example, selection of

fruit, grading/sorting, washing, peeling, and destoning, are

generally similar for the most of processed mango products.

Figure 15.5 shows process outline for the production of

various mango products.

Mango puree

Puree is a major processed product from mangoes and

serves as a base for a variety of mango products, for ex-

ample, nectar, beverages, jam, jelly, squash, and leather.

Generally, the terms

pulp

and

puree

are used interchange-

ably, though a puree is more “refined,” having less fibrous

Search WWH ::

Custom Search