Agriculture Reference

In-Depth Information

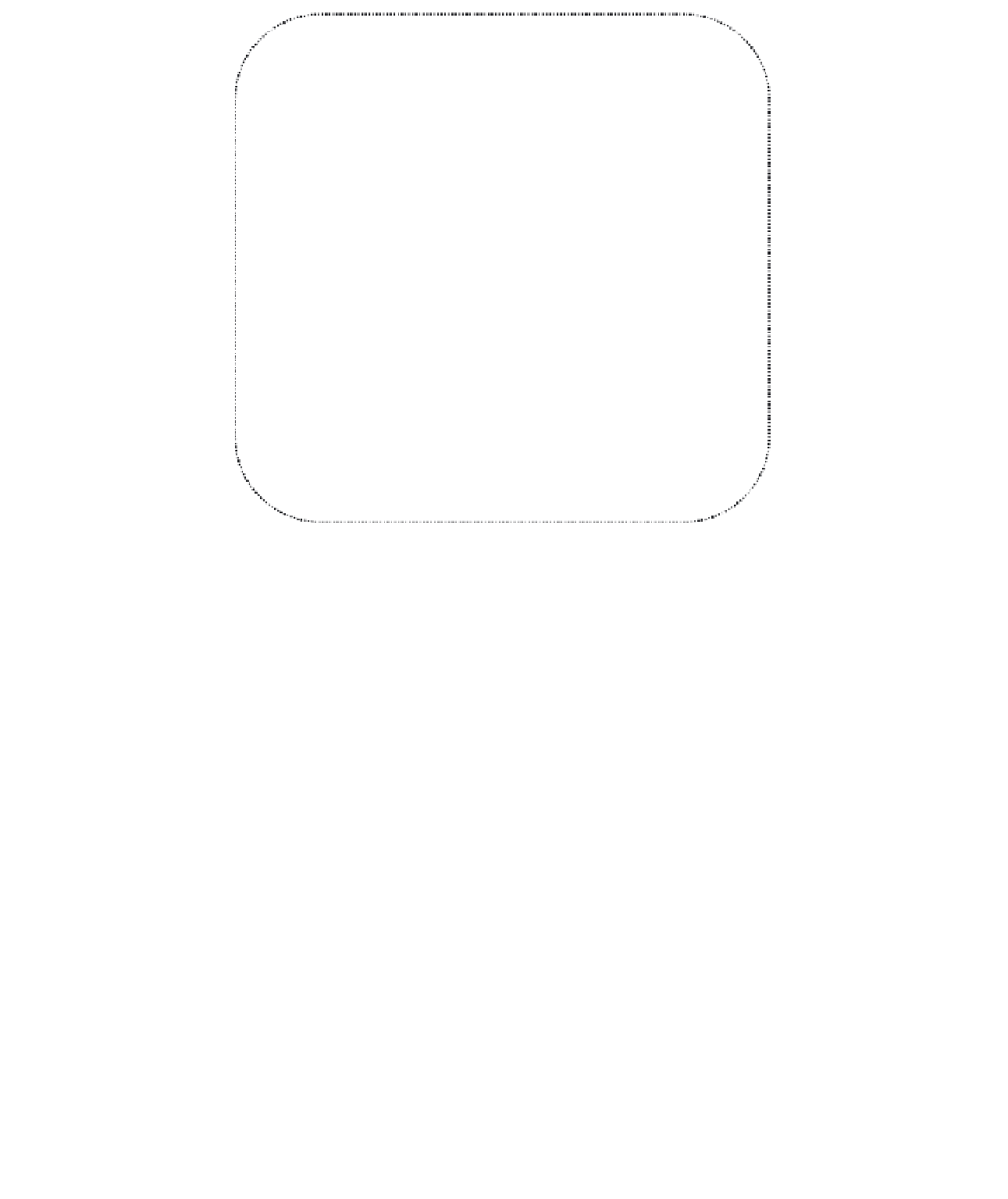

Natural

compounds

Controlled/modified

atmosphere

Heat treatments

Ultraviolet light

Edible coating

FRUITS

Increase in synthesis of secondary metabolites and antioxidant enzymes

Phenolics

phenolic acids,

flavonoids ,

lignans

Carotenoids

carotenes ,

xanthophyls

Others

glutathione

Enzymes

*SOD, CAT, POD,

ascorbate -

glutathione cycle

Improvement in sensorial

, safety and nutraceutical quality of the fruit

Antimicrobials

Antioxidants

Volatile compounds,

color potential

*SOD-Superoxide dismutase, CAT-Catalase, POD-Peroxidase

Figure 15.2.

Controlled postharvest stress-type applied to tropical fruit which induces the synthesis of

secondary metabolites and antioxidant enzyme system increasing their sensorial, safety, and nutraceutical

quality (source: Gonz alez-Aguilar et al., 2010).

or use of modified atmosphere packaging (MAP) has been

shown to prolong the shelf life of fresh-cut slices (Gorny

et al., 1998).

Pretreatments

Pretreatments are applied both directly to the cut fruit sur-

face or prior to cutting to the intact fruit, the latter be-

ing more convenient since it is easier to manipulate less

fragile whole fruit. However, antioxidant treatments, firm-

ing agents, or coatings are commonly applied to minimize

discoloration, retain firmness, other sensory attributes and

shelf life. A discussion of various pretreatments reported in

the literature follows.

Ethylene has an undesirable effect on the quality of

fresh-cut fruit. Its production is enhanced by wounding dur-

ing fresh-cut processing and the accumulation of this gas

within the packages of fresh-cut fruit can be detrimental to

their quality and shelf life. Exposing partially ripe fruit to

1-methylcyclopropene (1-MCP), an ethylene action in-

hibitor, before or after cutting may be a useful supplement

to proper temperature and relative humidity management

and chemical dips for maintaining quality of fresh-cut fruit.

Application of 1-MCP to whole mangoes prior to cutting

maintained firmness and light color of 'Tommy Atkins',

fresh-cut pieces, but it did not delay ripening of 'Kent' cul-

tivars (Plotto et al., 2003). Softening and browning were

Fresh-cut mango processing

Mangoes are generally processed into either longitudinal

slices or 1.5-2.0 cm cubes (dices) for fresh-cut market.

Fresh-cut mangoes can be prepared from different stages

of ripeness, that is, mature green, quarter ripe, half ripe, and

firm ripe. However, Allong et al. (2000) found that mature-

green fruit was not very suitable for fresh-cut products

owing to a lack of sensory quality (especially a character-

istic aroma) and short shelf life. The processing steps for

fresh-cut mangoes are similar to those for most other fruits.

A typical fresh-cut mango processing outline is shown in

Fig. 15.3.

Low storage temperature, controlled atmosphere (CA),

MAP, treatments with calcium salts, antioxidants, and/or

enzymatic browning inhibitors, or any combination of the

above is effective in prolonging shelf life of fresh-cut man-

goes (Chantanawarangoon, 2000; Gonzalez-Aguilar et al.,

2000; Rattanapanone et al., 2001; Chiumarelli et al., 2010).

Search WWH ::

Custom Search