Agriculture Reference

In-Depth Information

Puree/pulp derivates

A number of products may be produced from guava

puree/pulp such as juices, toppings, ice creams, jams, and

jellies. The selection of guavas for these products is limited

to the removal of rotten and damaged fruits because the dif-

ferences in size and flesh firmness are irrelevant since the

material will be homogenized and standardized according

to the soluble solids/sugar content. Generally, fully ripened

fruits with firm consistency and attractive color (for red

varieties), high acidity and ascorbic acid content, but with

few seeds are preferred for puree processing (Martin and

Kato, 1988). However, the part of the seeds and flesh that

are removed from the fruits for the processing of osmoti-

cally dehydrated or canned guava may also be used in puree

processing.

The fruits must be properly washed and sanitized before

being chopped or sliced. The chopped guava may either

be mashed or grinded in a pulper. The pulper removes the

seeds and fibrous material from the tissue besides forcing

the remainder of the product through a perforated screen.

However, in the absence of a pulper, a sieving step may

also be used for this purpose. After the pulper, the puree

may either be passed through a finisher or through a mill to

remove or grind the stone cells, respectively. Care should

be taken in this latter technique since the incorporation of

a large amount of stone cells into the puree may discolor

it (Yusof, 2003). Another method for puree extraction con-

sists of cooking the fruit before pulping it, which may lead

to degradation of the vitamin C and other labile compounds,

reducing the quality of the final product (Martin and Kato,

1988). After production, the guava puree may be preserved

by freezing (frozen guava puree), chemical preservatives,

canning (canned guava puree), or by using aseptic pack-

aging prior to being destined for other processes (Martin

and Kato, 1988; Adsule and Kadam, 1995; Dauthy, 1995)

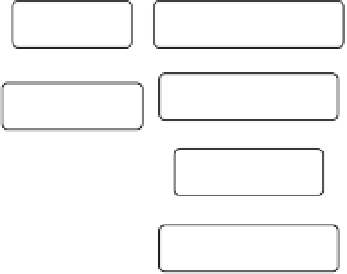

(Fig. 11.4).

Some characteristics of the fresh guava puree obtained

from both white and pink fruits are given in Table 11.2.

Raw guava

Sorting

Washing/Sanitizing

Cutting/Slicing

Cooking

Pulper

Finisher

Preservative

addition

Pasteuri

zation

Sterili

zation

Packing

Hot filling

Cooling

Freezing

Packing

Cooling

Packing

Storage at room

temperature

Storage

Storage

Figure 11.4.

Flow diagram of guava puree processing.

Search WWH ::

Custom Search