Agriculture Reference

In-Depth Information

Drying

Drying is used for either the production of guava infusions

or guava snacks. In the first case, unripened fruits are usu-

ally used, and guavas are sliced transversally to the central

axis. Drying is carried out without previous treatment, and

the fruit must be rehydrated before consumption.

Conversely, for the production of guava snacks, the seeds

are usually removed. The guava shells (halved fruits without

seeds) may be cut into thin slices (from 16 to 32 slices per

fruit) or small pieces prior to drying. Pretreatments such

as blanching and OD are usually carried out in order to

improve the color, texture, and nutritional characteristics

of the dried product. Dried guavas pretreated by OD were

found better in quality as evaluated by a sensory panel,

with improved color and flavor and greater sweetness and

juiciness than fruits without such a pretreatment (Sanjinez-

Argandona, 2005).

Raw guava

Sorting

Washing/Sanitizing

Peeling

Cutting/Slicing/Seed removal

Washing/neutralization

Canning

Cooking

Exhaustion

Draining

Canning in syrup

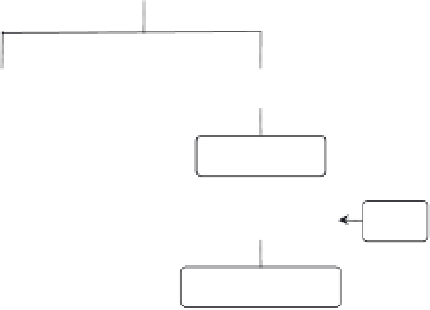

Canned guava (guava in syrup) is produced by thermal

processing the fruits in sucrose and/or glucose solutions

(

Pasteurization

Bottling

Syrup

Cooling

Pasteurization

35

◦

-40

◦

Brix). Artificial sweeteners may be used to sub-

stitute sugar for the processing of diet products. Sometimes,

a preservative and acidulant such as sorbic acid, sodium

benzoate, potassium sorbate, and/or citric acid is added to

the syrup. More frequently, the guavas are processed in

halves with their seeds removed (guava shells), although

in some countries, such as Mexico, canning of the whole

fruit is not uncommon. The fruits may be cooked either

before or after canning (Fig. 11.3). In the first case, the

guavas are cooked in 40

◦

-50

◦

Brix syrup until soft. The

syrup is then drained and the fruits are bottled in fresh, hot

syrup before closure and pasteurization. In industrial pro-

cesses, the fruit and syrup are usually added together before

thermal processing. In both cases, after canning, a thermal

treatment is carried out with boiling water (10-20 min),

followed

∼

Cooling

Storage

Storage

Figure 11.3.

Flow diagram of canned guava

processing.

guava may be improved by the addition of calcium salts

in the syrup, allowing for a minimization of the negative

effects of temperature on the texture of the guava (Sato

et al., 2006).

Freezing

Though the effect of shelf life on some properties of frozen

guava, such as total acidity and the sensory properties has

been evaluated, there are not many studies concerning the

freezing of guava. It was observed that storage (

37

◦

-40

◦

C

by

fast

cooling

to

(Martin

and

Kato, 1988).

The effect of cooking time (up to 60 min) and temperature

(60

◦

-90

◦

C) on the mass transfer kinetics as well as on the

color and texture of red guava in syrup has already been

evaluated (Sato et al., 2005). Higher mass transfer rates

(water loss and sugar gain) were observed within the first

30 min of processing. The effect of temperature was much

more significant than the time of processing on the color

of guava in syrup. The higher the process temperature, the

more intense is the redness of the fruit, although softening

may be observed with increasing temperatures, especially

for fruits processed at 90

◦

C. Thus the texture of canned

20

◦

C, up

to 6 months) of guava halves frozen in liquid nitrogen led to

a decrease in fruit acidity and rejection by the sensory panel

owing to loss of flavor and excessive softening (ICAITI,

1976).

This technique is not usually carried out with fresh fruit

since the fresh fruit is highly chill sensitive, being applied

more frequently for enhancing the shelf life of processed

products such as pulps.

−

Search WWH ::

Custom Search