Agriculture Reference

In-Depth Information

mass loss and decreased pectin methylesterase activity dur-

ing storage. Refrigerated guava immersed in 0.5% and 1%

calcium solutions maintained up to 16 days of postharvest

shelf life (Gonzaga-Neto et al., 1999).

The use of heat treatment can increase the shelf life of

fresh fruits due to inhibition of some postharvest diseases,

although excessive time/temperatures may scald and soften

the fruits. Guava scald is observed by the presence of brown

discolored regions and/or pits and sunken areas on the fruit

surface (Gould, 1994). Some studies have been carried out

to evaluate the effect of heat treatment on guava, showing

the possibility of completely reducing the occurrence of

anthracnose with a warm water bath (10 min at 50

◦

C), with

no influence on the soluble solids content, pH, titratable

acidity, or firmness (Ponzo, 2009).

The use of edible coatings has been also employed in

hurdle technology to reduce gas exchange and moisture

transfer between the fruit and its environment. Formulations

of edible emulsions containing starch, waxes, gelatin, or

acids have proven to be an efficient method of enhancing the

shelf life of guava. As compared to nontreated guava, coated

fruits exhibited lower weight loss during storage, which was

associated with the increase in shelf life and, consequently,

a decrease in postharvest losses (Oliveira and Cereda, 1999;

Fakhouri and Grosso, 2003; Ribeiro et al., 2005).

Several researchers evaluated the effect of 1-

methylcyclopropene (1-MCP) on delaying the ripening of

different varieties of guava by blocking the action of ethy-

lene (Basseto et al., 2005; Singh and Pal, 2008; Phebe and

Ong, 2010). It was generally observed that 1-MCP treat-

ment extended the shelf life of guava and maintained its

quality during both cold and ambient storage conditions.

However, very high concentrations of 1-MCP (900 nl/l, 6

or 12 hours) may inhibit fruit ripening and limit its subse-

quent flavor development (Basseto et al., 2005).

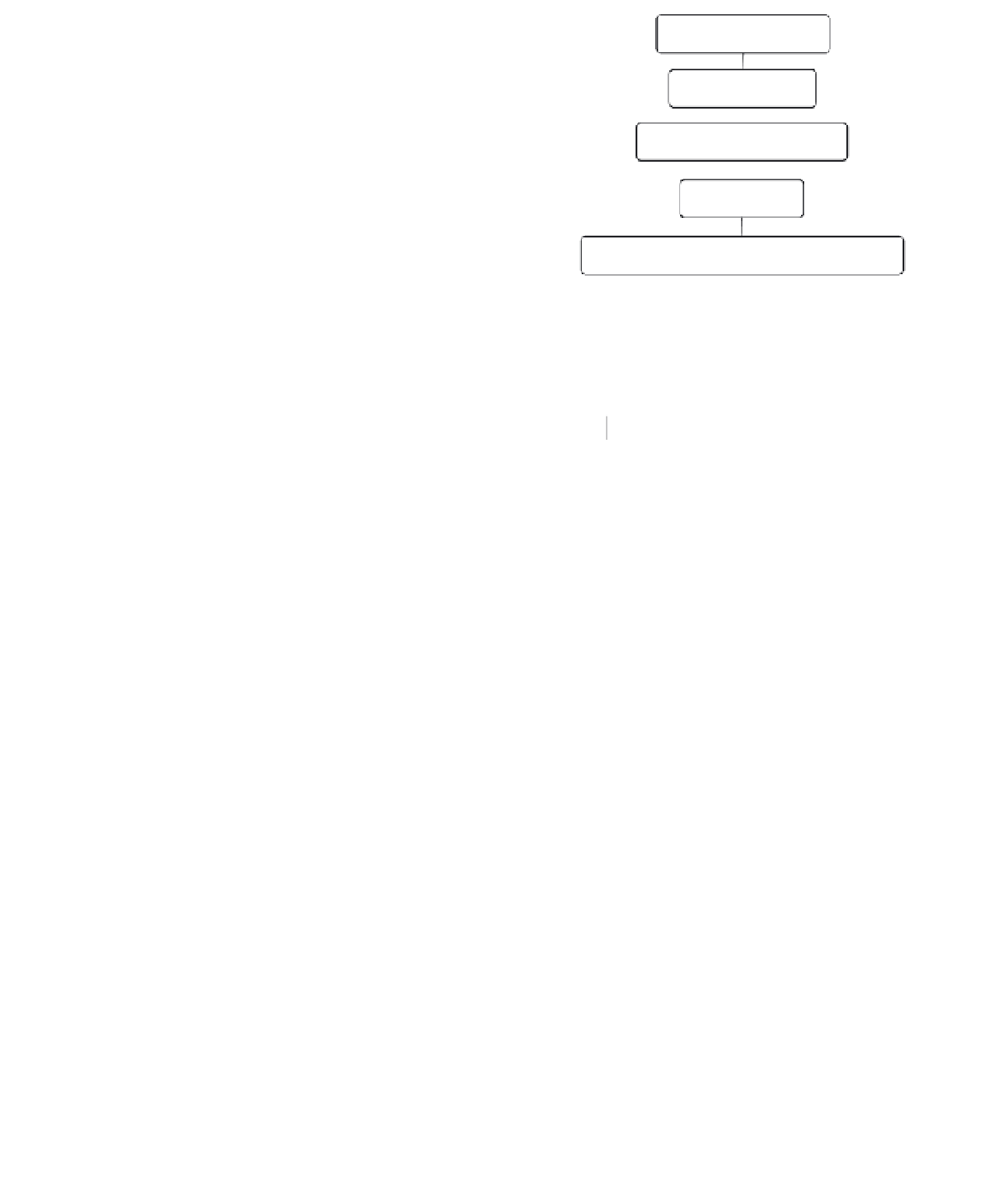

Harvest

Rapid cooling

Selection/Grading

Storage

Cleaning/Sanitization

Peeling

Cut in halves

Cut in slices

Seed removal

Washing

Cooling

Packaging

Distribution

Figure 11.1.

Flow diagram of minimal processing of

guavas.

is low, decreasing water loss and the cooling time in the

following steps (Mattiuz and Durigan, 2007).

The stage of maturity at harvest is one of the most im-

portant factors for the minimal processing of guava. As

observed before, the skin color generally determines the

ripening degree. According to Pinto et al. (2010), white

guava of the 'Kumagai' variety harvested at the light green

color are the most suitable, while red guava of the variety

'Pedro Sato' should be harvested at the yellowish green

maturity stage for minimal processing.

MINIMALLY PROCESSED OR

FRESH-CUT PRODUCTS

The main unit operations involved in the preparation of

fresh-cut guava are shown in Fig. 11.1 and described in this

section. The use of sanitary equipments and the adoption

of good manufacturing practices (GMP) as well as hazard

analysis and critical control points (HACCP) during the

whole processing are essential to maintain the high quality

of minimally processed guava (Garcia and Barrett, 2005).

Harvesting

The harvesting of guava should be carried out in the early

hours of the morning when the temperature of the fruits

Fast cooling, selection, and storage

Cooling is applied by immersing the fruits in cold water

tanks in order to decrease the metabolic activity of the

Search WWH ::

Custom Search