Agriculture Reference

In-Depth Information

Khodaparast et al. (2007) prepared breads using intact

and defatted powders of date pits in the formula at three lev-

els (5%, 10%, and 15%). The water absorption and dough

efficiency increased with addition of the powder. Breads

containing 5% of intact date pits powder was determined

as the best treatment when analyzed for sensory attributes of

aroma, taste, texture, and appearance. Hamada et al. (2002)

reported that by addition of date pits powder to bread, the

water is absorbed by the soluble fibers, and the water ac-

cessibility of starch will be limited, so the staling would be

retarded.

Other uses of date pits are as a soil organic additive

or as feed for various livestock (Banat et al., 2004). The

ground date pits could be used as filler in thermoplastics

and their oil content acts as a natural lubricant and eases

the molding process due to their significantly higher melt

flow index. Moreover, addition of about 20% date pits flour

to high-density polyethylene HDPE as a matrix gives a

significantly high modulus of elasticity for the resulting

composites (Ghazanfari et al., 2007).

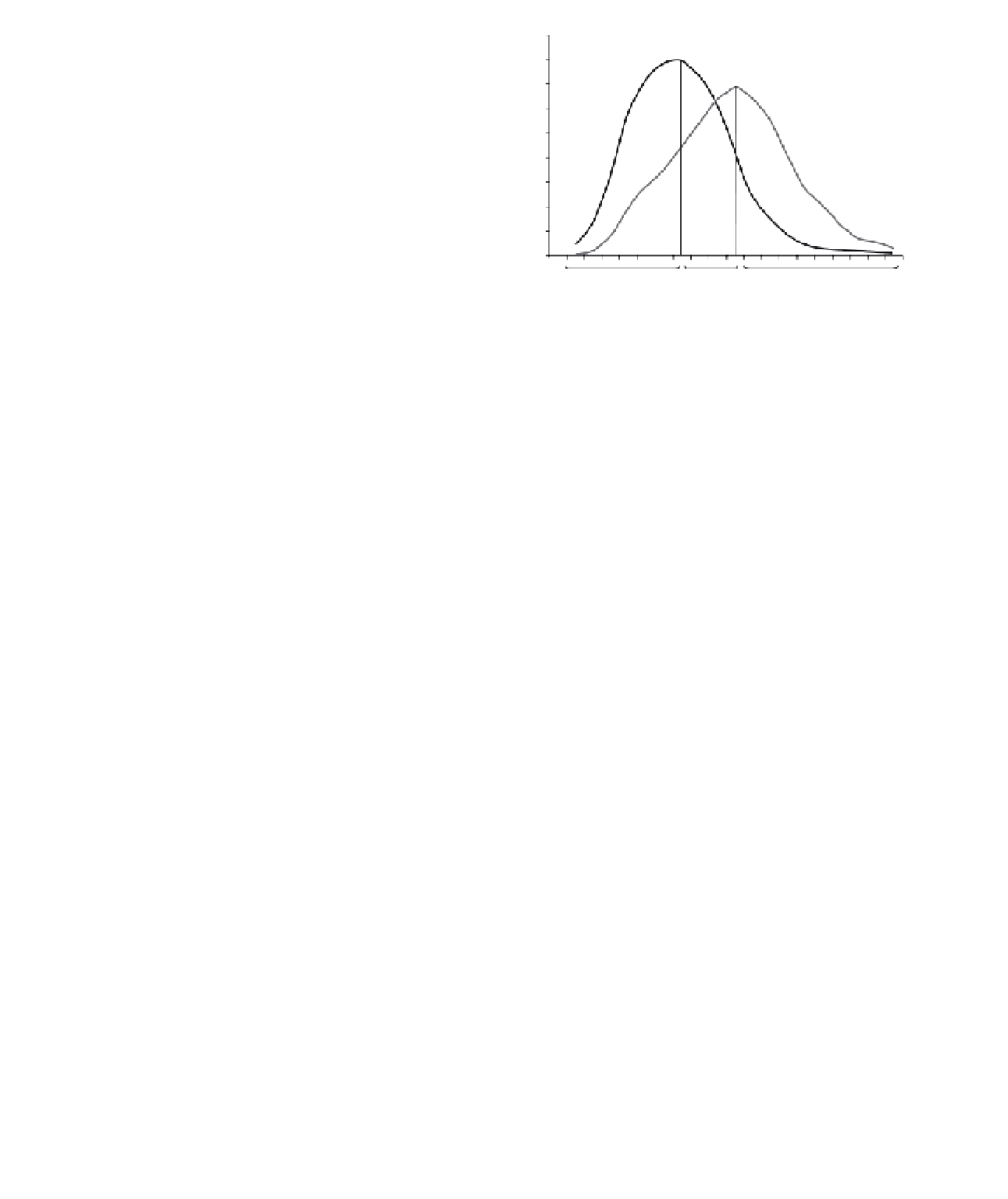

g/liter

Glucose

Fructose

II

I

III

Time

min.

Glucose-rich

fraction

Fructose-rich

fraction

Return

fraction

Figure 10.6.

Fractions removed out of the

separation column (source: Aleid, 2006).

(Paillat et al., 2000). Cation exchangers (Ca

2

+

) with pure

water as the eluent are commonly employed (Verhaar and

Kuster, 1981). Aleid (2006) reported a small scale process

for the separation of fructose from a mixture of sugars con-

taining essentially fructose and glucose, obtained from date

palm fruits. An aqueous solution of date syrup solutions

(20%, 30%, and 40% by weight) were added to a chro-

matographic column filled with Dowex polystyrene strong

cation-exchange gel matrix. After the date sugar solution

batch, a calculated quantity of water was added to the col-

umn. Glucose was retained by the resin more weakly than

fructose and proceeded faster into the water batch flowing

ahead (Fig. 10.6). A high yield of fructose is obtained at

70

◦

C column temperature with a flow rate of 0.025 bed

volume/min and date syrup solution containing 40% sugar.

However, with the 40% date syrup supply the average con-

centrations of glucose and fructose in the return fractions

were more than 40%, which can be used for diluting the

thick date syrup solution extracted from dates.

INNOVATIVE PROCESSING OF DATES

Biotechnology can help in finding ways for the utiliza-

tion of surpluses dates as raw materials for the produc-

tion of value-added products such as medical and industrial

ethanol, baker's yeast, fodder yeast, citric acid, vinegar, and

so on. Juice of date is one of the richest foodstuffs in neu-

tral compounds such as monosaccharides, disaccharides,

mineral salts, and vitamins. These substances are consid-

ered essential elements for the growth of microorganisms,

especially yeasts (ALBassam, 2001). Another knowledge

applied in dates processing is the machine vision technol-

ogy which could be used to enable quantity measurements

for qualitative criteria such as color. It is based on different

techniques such as image processing and pattern recogni-

tion (Fadel et al., 2001).

Fructose from date syrup

Fructose can be separated from dates to yield value-added

products. Traditionally, fructose has been obtained from

sucrose syrup produced by the cane and beet industries or

from syrup produced by enzymatic depolymerization and

hydration of starch-based carbohydrates such as corn and

potatoes. The proportion of fructose in these syrups is then

increased to 55-90% w/w by chromatographic separation

(Barker et al., 1984).

Separation is related to the stability difference of the

sugar-calcium complex: only polyols and certain sugars

(fructose, galactose) are capable of forming such a com-

plex. The other components (sucrose, glucose) do not form

a complex with the resin, thus resulting in the separation

Baker's yeast production from dates

Dates are potentially good substrates for baker's yeast pro-

duction serving mainly as source of carbon and energy.

Almost all of the baker's yeast is produced from molasses

using

S. cerevisiae

(Barnett et al., 2000). The optimum

growth temperature and pH for

S. cerevisiae

are 30

◦

Cand

4.5, respectively. The sugars in dates are mainly glucose

and fructose, which are easily assimilable to most micro-

organisms (Sawaya, 1986). To produce one kg yeast from

dates, about 3 mg d-Biotin, 150 mg D-pantothenic acid, and

2 g m-inositol are needed. These elements and compounds

must be provided in the production medium in enough

quantities and metabolizable forms. One ton of dates used

Search WWH ::

Custom Search