Agriculture Reference

In-Depth Information

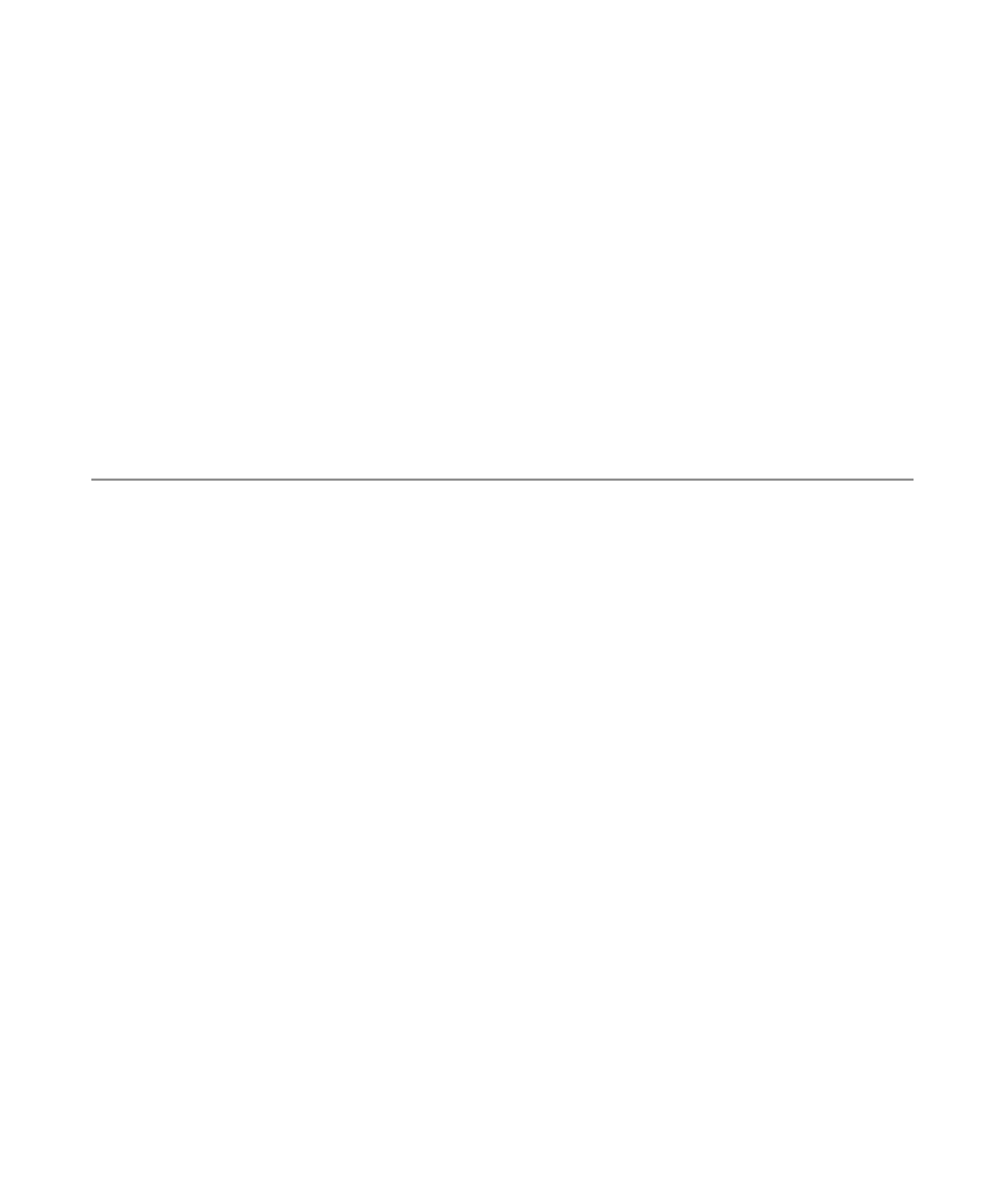

Table 9.7.

Some chemical characteristics of coconut oils.

Parameter

Ordinary Coconut Oil

Virgin Coconut Oil

Coconut Paring Oil

Iodine value (Wijs)

7.6-10.0

5.0-10.0

15.5-16.9

Saponification value (mg KOH/kg)

>

250

>

250

>

250

Unsaponifiable matter (%)

0.80

0.20

0.8

Free fatty acid (%)

<

0.8

<

0.2

<

0.8

Fatty acid composition (%):

C

6:0

0.52

0.20

0.12

C

8:0

4.50

7.80

3.14

C

10:0

4.20

6.50

3.15

C

12:0

48.60

50.60

38.60

C

14:0

21.20

19.50

21.67

C

16:0

9.10

6.50

12.67

C

18:0

2.80

1.90

4.12

C

18:1

5.80

4.50

14.22

C

18:2

2.60

2.50

2.15

C

18:3

Trace

Trace

Trace

MCFA

1

(%)

57.82

65.10

45.01

LCSFA

2

(%)

33.10

27.90

38.46

1

MCFA, medium-chain fatty acid, C

6:0

to C

12:0

.

2

LCSFA, long-chain saturated fatty acid, C

14:0

to C

18:0

.

Source: SLS (2002); Marikkar et al. (2007a).

milk (Naka, 2006). When coconut milk is allowed to stand

for more than 10 hours under favorable conditions, the oil

naturally separates from the water and the proteins. It ba-

sically operates as a curdling process, and the top oil layer

needs to be scooped off using a ladle. In this method, heat

is not provided for the extraction of oil, but the filtered oil

is heated to remove residual moisture to ensure a prolonged

shelf life (Bawalan and Chapman, 2006).

Typically, the extracted oil is boiled to bring the moisture

content down. Though this method is operationally simple

and require low amount of capital investment, its output ca-

pacity is not sufficient for a large-scale operation (Silveira

et al., 2004).

Screw press expeller machines which operate at low-

temperature conditions may also be employed for VCO

extraction. However, the use of partially dehydrated ker-

nels in the screw press might cause choking or blockage

of the equipment. In order to overcome this problem, fresh

kernels can be pulverized and then dehydrated to a mois-

ture content of 3%. Dehydration is carried out using hot

air at a temperature of around 60

◦

C. As the dehydration is

carried out at a relatively low temperature to minimize the

burning effect, the process takes longer time. For oil ex-

traction, low-pressure microscrew press expellers specifi-

cally designed for low-temperature operation are used. Ac-

cording to the VCO production guideline, the extraction

temperature has to be maintained

≤

60

◦

C; if the extraction

temperature rises above 60

◦

C, it can impart some discol-

oration and odor to the oil, and furthermore, it may affect the

quality of defatted kernel residue due to burning (Baensch

et al., 2004).

VCO production by dry process

Dry processing is another method used for VCO produc-

tion. In contrast to the wet method, fresh kernel has to be

dehydrated partially using a low-temperature drying sys-

tem. First, kernels are shredded into fine particles and dried

under controlled temperature to reach moisture content of

10-13%. After partial dehydration, a simple “squeeze test”

is performed to check whether oil is oozing out from the ker-

nel. If a milky emulsion appears in the test, the kernel needs

to be further dried. When the dried shredded kernel passes

this test, it can be subjected to hydraulic press extraction

to extract oil. Since oil is extracted from a relatively high-

moisture raw material, the crude oil produced has higher

amount of water, which must be removed before storage.

Search WWH ::

Custom Search