Agriculture Reference

In-Depth Information

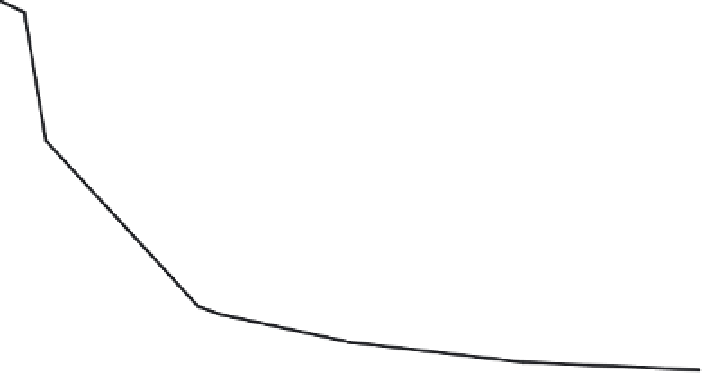

5

4.5

4

3.5

3

K(LDPE) = 0.057

2.5

2

1.5

1

LDPE Film

K(Film) = 0.17

0.5

Prototyping Film

0

0

10

20

30

40

50

60

70

80

90

100

Time (hr)

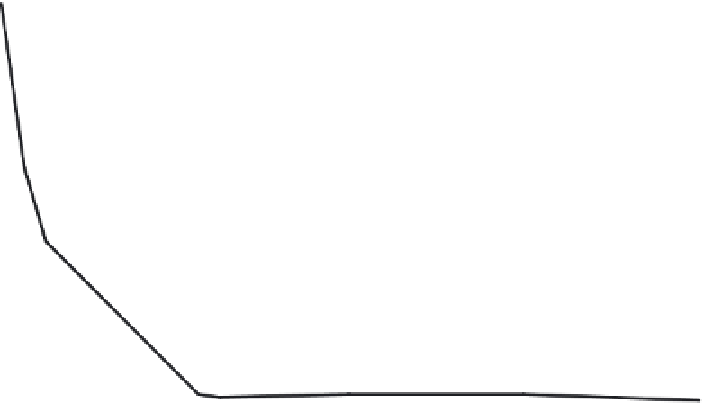

Figure 7.7.

Ethylene concentration inside the bag of composite film and commercial low-density polyethylene

(LDPE) film (initial concentration was 4 ppm) (reprinted with permission from Fuongfuchat et al., 2008).

CO

2

permeability (Sirikittikul et al., 2008). Developed high

ethylene-permeable bags (EP) by this research group were

tested on acetylene treated mature green banana (Klintham

et al., 2010). It was found that ethylene-permeable bags

slowed down ripening process of banana and prolong shelf

life to 14-17 days. Bananas stored in air, at 13

◦

Chada

shelf life of 5-8 days, and bananas in BOPP and LDPE

bags had a shelf life of 4 days. High oxygen permeable film

also exhibited a positive result on extended shelf life; how-

ever, low ethylene accumulation of 0.4 ppm was measured

in high ethylene-permeable bags.

coatings can be produced from three major types of biopoly-

mers, including polysaccharides (carbohydrates and gums),

proteins and lipids (Lin and Zhao, 2007), and food-grade

additives such as plasticizers. Research efforts over several

decades have continued in studying and developing edible

films and coatings for food products, which were exten-

sively published and reviewed (Kester and Fennema, 1986;

Han, 2005; Han and Gennadios, 2005).

Previous studies on edible coatings for tropical fruits

include potato starch-based coatings for guava (Quezada

Gallo et al., 2003), edible coating for preserving kiwifruit

at ambient temperature (Xu et al., 2001), chitosan films and

coatings for mangoes (Srinivasa et al., 2002; Chien et al.,

2007; Dang et al., 2008), and coatings of carboxymethycel-

lulose containing maltodextrin for retaining visual quality

and flavor of fresh-cut mango (Plotto et al., 2004). Other

major endeavors in this field also involve developing effec-

tive edible films and coatings for fresh fruits from a new

material and/or new approach of film formation (such as

blended or composite films) as well as experimenting the

use of fruits/vegetable purees as the edible films (McHugh

et al., 1996; Sothornvit and Rodsamran, 2007).

Besides permeability and mechanical integrity, wettabil-

ity is another key factor to ensure effective film products,

whereas all these factors should be optimized. Effective

Edible coatings/films

Edible films and coatings can be considered one class of ac-

tive packaging technology, owing to the extra functions of

the edibility and biodegradability of the films and coatings

(Han, 2002), and/or additional functions of the films and

coatings besides the ordinary barrier against oil, gas, and

water vapor. Edible films and coating have generally been

used to prevent moisture loss, improve appearance, and ex-

tend shelf life of fruits. Additional functions can arise from

the use of edible films/coatings as carriers of active addi-

tives or substances such as antimicrobials, antioxidants, fla-

vors, and colors (Krochta and De Mulder-Johnston, 1997;

Han and Gennadios, 2005). In general, edible films and

Search WWH ::

Custom Search