Agriculture Reference

In-Depth Information

35

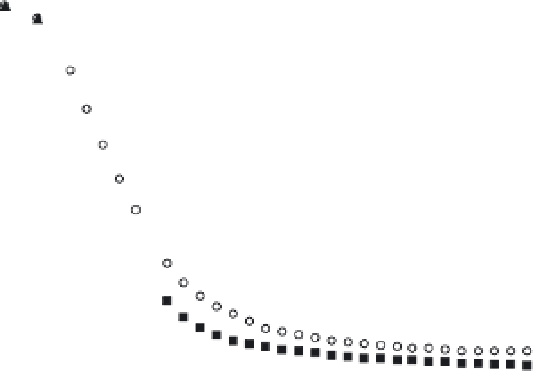

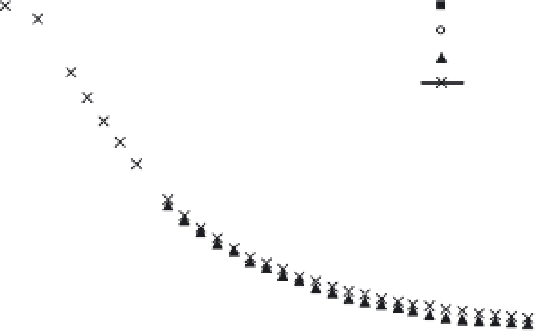

RPC

CCF

RSC

FTD

30

25

20

15

10

0

120

240

360

480

600

720

840

960

Time (minutes)

Figure 7.2.

Cooling rates of pineapples (cv. Phuket) in various shipping containers stored at 12

◦

C(RPC

=

reusable plastic container; CCF

=

corrugated common footprint tray; RSC

=

regular slotted container; FTD

=

full telescope design style container). Container dimensions are 400

×

300 mm. RSC and FTD containers have

four holes (ø 25 mm) on each side of the length panels.

common footprints have been developed by the Fiberboard

Box Association (FBA) and the European Federation of

Corrugated Board Manufacturers (FEFCO). The systems

require standardized dimensions and stacking features to al-

low containers in varying designs and features from various

manufacturers, which conform to common footprint con-

figurations securely stacked on the European pallet (120

stores or in shipping containers either in RPCs or corru-

gated common footprint systems as previously described.

Plastic packaging, such as plastic bags or plastic trays with

heat-sealed film lids, is commonly used to protect the fruits

from contamination, and extend the shelf life of fresh fruits

and fresh-cut fruits. Proper matching of a film's permeabil-

ity with a fruit's respiration could create properly modified

atmospheric conditions in maintaining quality of the fresh

and fresh-cut fruits.

Ideally, the selection of packaging should consider the

characteristics of fresh fruits, including both physical and

physiological characteristics. Packaging, in one way or

another, performs a function as a marketing tool. How-

ever, for fresh fruits, packaging plays this role to a lesser

extent compared to processed fruits, as fresh fruits pri-

marily present themselves. Therefore, packaging for fresh

fruits, either display-ready shipping containers or retail

packaging, should clearly display or enhance the presen-

tation of the packed fruits. In addition, the branding pre-

sented on the packages helps promote the reliability of

the products.

Information about fresh fruits is increasingly required by

consumers such as types and manufacturers as well as nu-

trition facts. This information about fresh fruits is generally

conveyed through packaging by labeling or printing on the

retail packaging. Tracking and tracing using RFID or other

×

100 cm) and the Grocery Manufacturers' Association

(GMA) pallet (48

40 in) commonly used in North

America. Configurations of full-size and half-size common

footprint containers are 60

×

30 cm,

respectively. RPC also conforms to the corrugated com-

mon footprint system. The open-tray design of corrugated

common footprints has overcome the cooling drawback of

corrugated containers as compared to RPCs. However, the

systems are not commonly being used in many countries

in tropical and subtropical regions. Figure 7.3 shows

mangoes packed in various package designs versus new

Michigan State University standardized package design

(Singh and Saha, 2010).

There are a wide variety of forms and materials used for

retail packaging of fruits; the most common types are plas-

tic bags, plastic trays with overwrapped film or heat-sealed

film or clamshell trays, and plastic net bags. Retail packag-

ing is developed in response to consumer's requirements.

Fruits may be displayed in plastic containers of the retail

×

40 cm and 40

×

Search WWH ::

Custom Search