Agriculture Reference

In-Depth Information

resistant to PEF than

S. enteritidis

and

E. coli

in both juices

when treated at the same processing conditions.

of temperature, which is also another benefit of OH. Fur-

ther incorporating electrolytes such as salt can enhance the

electrical conductivity.

In continuous processes, the product flows continuously

throughout the heating, holding, and cooling sections simi-

lar to pasteurization of liquid foods, except the process can

handle particulates. Viscous slurry is pumped to the contin-

uous flow OH system via a feed pump. The slurry is passed

through a series of electrodes in the OH column followed

by the holding section where the product retains for a def-

inite residence time to achieve commercial sterility. The

product then passes through cooling section and packed

aseptically.

The major factors influencing particle velocity in a

stream of carrier fluids are viscosity, relative density (par-

ticle to fluid), relative size (particle to tube), particle shape,

and concentration of the solid phase in the fluid (Chan-

darana and Unverferth, 1996). Therefore, it is essential to

have a good knowledge of the physical, mechanical, ther-

mal, and electrical properties of the particles and the carrier

fluid to develop continuous thermal processing. The uses of

food compatible electrodes, which are currently available,

produce correct electrical current density.

A 75 kW system is in operation at the Wildfruit Products

Division of Nissei Co. Ltd. in Japan, where it is running

a variety of fruit products. These products are filled into

10 liter bags for the food service and dairy markets.

OHMIC HEATING

Ohmic heating is referred to as Joule heating, electrical re-

sistance heating, or electroconductive heating. Ohmic heat-

ing (OH) is defined as a process where electric currents are

passed through foods or other materials using a variety of

voltage and current combinations with the primary purpose

of heating. Heat is generated volumetrically, resulting in

rapid and uniform heating of the product, and the product

does not experience a large temperature gradient within it-

self. The major advantage of the OH process is that all of

the components of the product flowing through the two-

phase food system, including fluid and particulates, which

are heated virtually simultaneously. Even it is reported that

it is possible to heat the center of the solid particle faster

than the liquid (Sastry and Palanippan, 1992; Tulsiyan et al.,

2008). Thus it is unnecessary to overcook the liquid phase

in order to sterilize the particulates.

OH has potential in a large number of food processing

applications and the technique is currently being used for

the processing of whole fruits in Japan and the UK (Sastry

and Barach, 2000). The US Food and Drug Administration

(FDA) is currently considering the OH process for com-

mercialization in the United States.

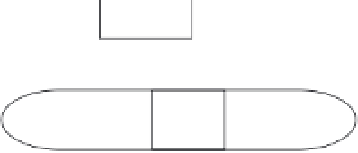

The OH is based on the passage of electrical alternat-

ing current (AC) through a body like a liquid-particulate

system, which serves as an electrical resistance. The nov-

elty of such electric heating system is on direct transfer of

energy from the electromagnetic source to the food mate-

rial without heating the heat transfer surface. AC voltage

is applied to the electrodes at both ends of the product's

body (Fig. 5.6). The rate of heating is directly proportional

to the square of the electric field strength and the electri-

cal conductivity. The electrical conductivity may be varied

by appropriate selection of electrode distance or voltage

applied. The electrical conductivity increases as function

OH treatment of fruits

Much research has been carried out on the electrical con-

ductivity of fruit products (Palaniappan and Sastry, 1991;

Castro et al., 2004; Icier and Ilicali, 2005). Measurements

of

σ

of different fruits (peach, pear, and pineapple) are

available in the literature (Mitchell and de Alwis, 1989;

Castro et al., 2003; Sarang et al., 2008). The electrical con-

ductivities of fresh fruits (peach, pear, and pineapple) were

found to increase linearly with temperature in the wide

temperature range between 25

◦

and 140

◦

C (Sarang et al.,

2008). Within fruits, peach was more conductive than pear

and pineapple.

AC power

Inactivation of enzyme

Inactivation of enzyme is a necessary step for fruits process-

ing, however, application of OH for inactivation of enzymes

is limited. Castro et al. (2004) compared the deactivation of

different enzymes samples heated with ohmic or conven-

tional heating. They showed that the electrical field applied

during OH caused the faster deactivation than the conven-

tional heating. Leizerson and Shimoni (2005) observed that

OH reduced pectinmethylesterase activity by 98%.

Food

Figure 5.6.

Schematic for a typical ohmic heating

unit.

Search WWH ::

Custom Search