Agriculture Reference

In-Depth Information

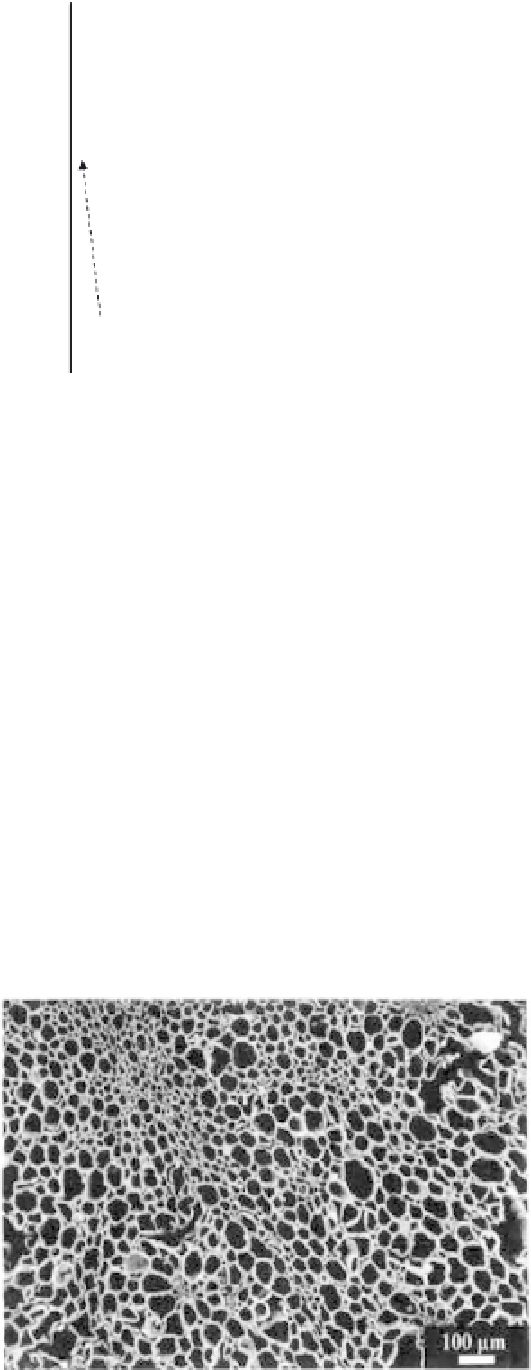

the inner zones was negligible. Fruits that had been frozen

by HPSF method maintained an acceptable microstructure

supported by SEM micrographs. The cells are arranged ad-

jacently without clear breakage, demonstrating that this is

the best freezing method for preserving fruit microstruc-

ture.

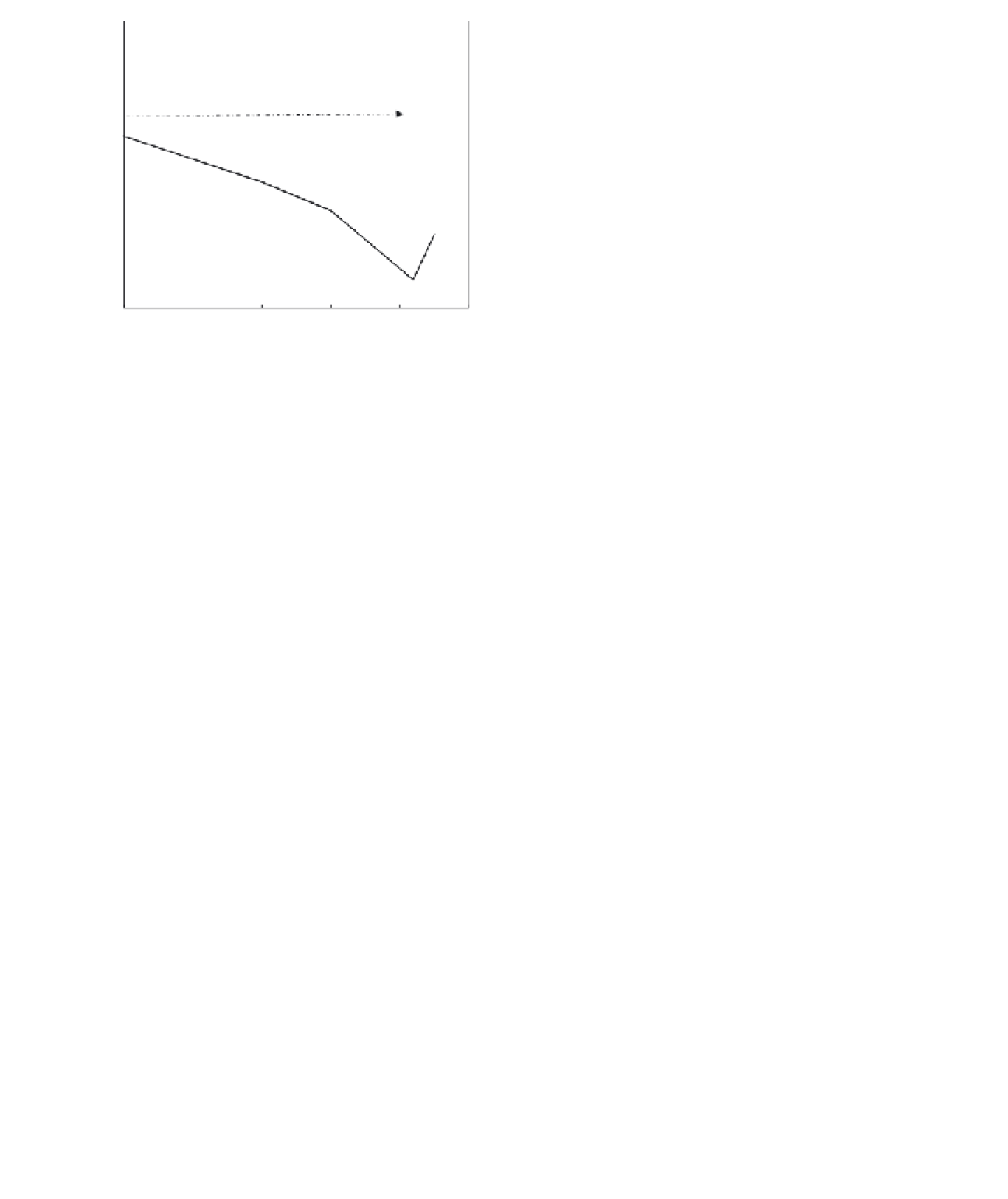

20

10

Compression

0

LIQUID WATER

Cooling

-10

Freezing

PULSED ELECTRIC FIELD PROCESSING

The potential to commercialize the nonthermal PEF tech-

nology as a new method to preserve food products has

caught the attention of the food industry that wishes to

fulfill consumers' demands for fresh products (Wouters

et al., 2001). The pulse electric field (PEF) treatment, or

high-intensity pulsed electric field (HIPEF), is one of the

best suitable techniques for fruit processing, and the tech-

nique has emerged as a promising alternative to conven-

tional pasteurization (Sizer and Balasubramaniam, 1999;

Toepfl et al., 2007). It is expected that application of PEF

treatment would be less detrimental than heat treatment for

plant tissue ingredients like pigments, vitamins, and fla-

voring agents. This process has been studied as a nonther-

mal treatment for food pasteurization (Eshtiaghi and Knorr,

2002). However, the PEF technology is mostly suitable for

liquid foods to increase their shelf life while maintaining

the sensory attributes.

During the past few years, a significant effort has been

made to use this technology on a commercial scale for

pasteurization of food (Huang and Wang, 2009). The PEF

treatment of liquid foods is based on the application of

high-intensity electric field (typically 20-80 kV/cm) to the

food product as it flows between two electrodes. Gener-

ally, PEF treatment systems consist of (1) a pulse gener-

ator, (2) treatment chambers, (3) a fluid-handing system,

and (4) monitoring systems (Rivas et al., 2006). The PEF

treatment chamber is used to house two electrodes and

deliver a high voltage to the food material. A schematic

of PEF treatment of fluid food is illustrated in Fig. 5.5.

The design of the treatment chamber is one of the im-

portant factors in the development of the PEF treatment

for nonthermal pasteurization, as it should impart uniform

electric field to foods with a minimum increase in tem-

perature, and the electrodes should be designed to mini-

mize the effect of electrolysis (Toepfl et al., 2006). The

PEF may be applied in the form of exponentially decaying,

square wave, bipolar, or oscillatory pulses and at ambient,

subambient, or slightly above ambient temperature. Dura-

tion of pulses is in seconds. The key variables involved in

PEF are electric field strength (

E

), pulse duration or pulse

width (

τ

), treatment time (

t

) pulse repetition rate (

f

), wave-

form of the pulse, and treatment temperature. Huang and

ICE I

-20

Pressure release

-30

0

50

100

150

200

250

Pressure (MPa)

Figure 5.3.

High-pressure shift freezing process

(broken line, process path; solid line, pure water) P-T

phase diagram.

2 sec, and the freezing process is completed at atmospheric

pressure, lowering the refrigeration temperature down to

-25

◦

C. Since the product has already been supercooled to

almost -21

◦

C, the sudden change in pressure causes an

instantaneous conversion of the supercooled sensible heat

to latent heat, resulting in instantaneous ice nucleation.

Approximately 20% of the free water gets instantaneously

converted to ice nuclei.

Otero et al. (2000) studied modifications on the mi-

crostructure of peach and mango produced by HPSF. The

high level of supercooling leads to uniform and rapid ice

nucleation. The HPSF produced no appreciable damage at

the surface of the sample for the surface zone of peach

frozen by high pressure (Fig. 5.4), and also, damage in

Figure 5.4.

SEM micrograph of peach frozen by

HP-shift freezing (source: Otero et al., 2000).

Search WWH ::

Custom Search